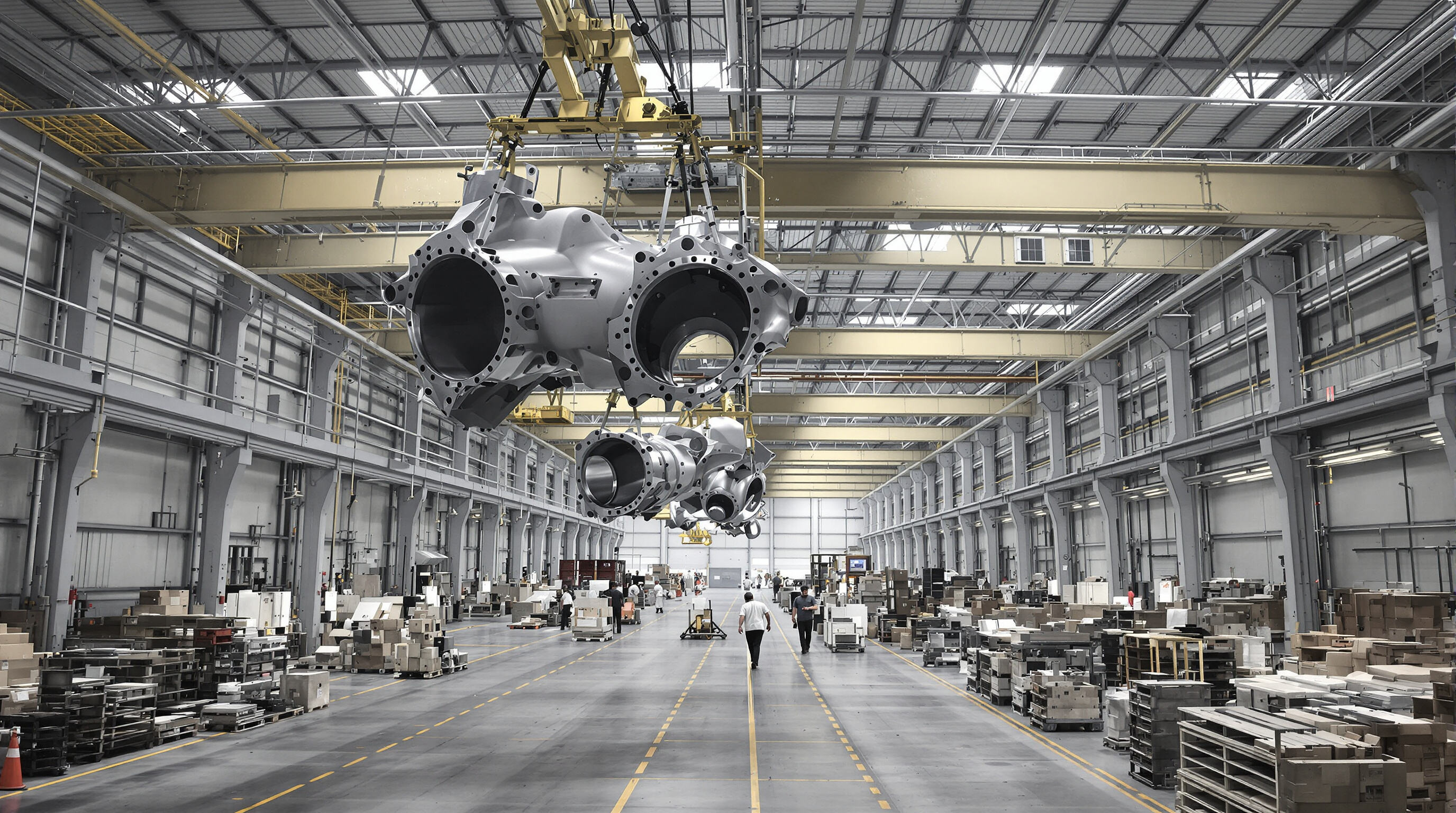

Freeing Floor Space by Moving Material Handling Overhead Crane

According to the 2024 Manufacturing Space Optimization Report, overhead cranes can free up about 40% of workshop floor space when they take the place of ground equipment such as forklifts. By going vertical instead of horizontal, factories find themselves with extra room to set up new assembly areas, stage inventory better, or even create those much needed safety buffers between work zones. Some facilities have actually seen workflow interruptions drop by around 22% after implementing these kinds of space saving measures, mainly because there's just less equipment moving back and forth across the same pathways all day long.

Reducing Congestion and Improving Workflow Continuity

By establishing dedicated aerial pathways, overhead cranes decrease aisle-blocking incidents by 57% compared to traditional material handling (PwC Operations Review 2023). This creates continuous production flows where:

- Components move directly from receiving to assembly

- WIP (Work-in-Progress) transfers happen without intermediate staging

- Finished goods travel overhead to packaging/shipping zones

Comparative Benefits in Compact vs. Large-Scale Manufacturing Layouts

The space-saving impact varies by facility size:

| Layout Type | Floor Space Reclaimed | Throughput Gain |

|---|---|---|

| Compact (<50k sq ft) | 60% | 35% |

| Large-Scale (200k sq ft) | 30% | 18% |

Compact facilities benefit most from overhead material handling systems, while larger plants achieve proportional workflow improvements through zoned crane operations. Both configurations show measurable efficiency gains when integrating vertical material movement protocols.

Enhancing Safety and Precision in Heavy Load Handling

Minimizing workplace risks through controlled overhead lifting

Using overhead cranes cuts down on ground level dangers because they lift loads off the floor instead of moving them across it. Studies from OSHA show these cranes cut collision risks by around 63% when compared to regular forklift work. The cranes come equipped with all sorts of safety features too. Things like load limit sensors and automatic emergency brakes stop situations where too much weight gets lifted at once. These overloads are actually one of the main reasons we see industrial accidents happen, costing companies an average of $740,000 per incident according to Ponemon research last year. And there's another benefit worth mentioning: remote control options let workers handle materials without standing right underneath them, so nobody has to worry about getting hit by something falling or caught in dangerous pinch points while things get moved around.

Achieving exact load positioning for critical assembly tasks

Hoists built with about 1mm positioning accuracy let workers place turbine blades, press molds, and expensive parts exactly where they need to go. These machines come with smart features such as programmable height settings and sway control systems that keep things stable even when moving uneven 20 ton weights around. The level of accuracy makes a real difference on factory floors. According to tests from the National Institute of Standards and Technology, manufacturers see roughly half fewer mistakes during assembly processes in aerospace production when using these precise lifting solutions.

Documented reductions in injury rates after crane implementation

Over three years, researchers looked at 127 different manufacturing facilities and found that switching from manual lifting to overhead cranes cut down on musculoskeletal injuries by almost 60%. Plants that installed radio controlled anti collision systems had an impressive 82% drop in those annoying impact incidents compared to older pendant operated models. The numbers really speak for themselves when we look at Wuhan Rayvanbo's automotive customers who haven't had any lost time injuries during engine block installations since early 2021. These stats aren't just numbers on paper they show how proper implementation of overhead handling equipment can completely change workplace safety standards.

Integrating Overhead Cranes into Modern, Automated Production Systems

Role of overhead cranes in Industry 4.0 and smart factory environments

The old overhead cranes we used to see around factories are becoming something much smarter these days, really helping push forward what Industry 4.0 is all about. When connected to those manufacturing execution systems (MES) and warehouse management programs, modern cranes can actually change their behavior according to production needs while constantly talking to other machines on the factory floor. We've seen stats showing this kind of system cuts down on manual work by about 35% during assembly operations, which means materials move smoothly from robot stations right into storage areas without so many stoppages. Big name manufacturers have started putting RFID scanners right into their cranes now. These scanners check if parts are available where they need to be and then reroute things as demand changes throughout the day, making sure nothing gets stuck waiting for components.

IoT and digital controls for real-time monitoring and predictive maintenance

Today's overhead cranes come equipped with smart load sensors connected to the internet and use something called digital twin tech to give operators a much clearer picture of what's going on. These machines have vibration sensors that can spot problems with bearings three days before they actually fail, and there are special programs running in the background that figure out how to save energy during different work shifts. According to a report from Smart Manufacturing last year, factories that adopted this kind of predictive maintenance saw their unexpected downtime drop by around 40%, which is way better than just doing regular inspections manually. Technicians can now fix problems remotely through augmented reality displays thanks to wireless controls, and this has cut down troubleshooting time by almost two thirds in important manufacturing areas such as making batteries for cars.

Future trends: AI-driven routing, automation, and collision avoidance

AI is starting to transform how cranes operate these days, thanks to smart systems that look at past workflow data through neural networks. Some early tests show that machine learning can boost pallet routing efficiency quite a bit - about 28% improvement in busy foundry environments where it predicts where crews will move and detects temperature shifts in metal parts. The latest safety tech for cranes mixes LiDAR maps with ultra wideband location tracking to create moving safety zones around people working nearby. Most experts think around seven out of ten new overhead cranes will come with built-in robot connection points by the end of this decade. This means automatic tool switches and smooth transfers between cranes and those self-driving warehouse vehicles without needing someone to coordinate everything manually.

Flexibility and Scalability Across Diverse Manufacturing Applications

Customizing Overhead Cranes, Hoists, and Monorails for Specific Production Needs

Today's manufacturing operations need overhead crane systems that match their specific needs on the shop floor. The market offers everything from small single girder cranes used in places where space matters most, like electronics factories, all the way up to those big double girder models with special rotating hooks needed in steel mills. Many plants are adding extra equipment these days too. Take vacuum lifters for instance they're becoming popular in glass manufacturing because they handle fragile panels so gently. Automotive plants have started using modular monorail systems instead of traditional overhead cranes in several areas. These setups allow materials to move smoothly around the facility without having to tear out walls or ceilings just to install new infrastructure.

Modular Crane Solutions for Adaptable and Expandable Operations

Modular overhead crane systems enable factories to adapt to shifting production volumes through:

- Interchangeable runway beams for reconfiguring workspace layouts in â€48 hours

- Scalable lifting capacities (1–100+ tons) via upgradable hoists and trolleys

- Hybrid manual/automated controls for phased transitions to Industry 4.0 workflows

A 2023 Material Handling Institute study found facilities using modular cranes reduced reconfiguration costs by 32% compared to fixed systems.

Case Study: Scalable Systems in Varied Industrial Settings

One major supplier in the industrial sector rolled out standardized overhead cranes at their eight different sites, which gave them around 94% compatibility between components across locations. When markets changed direction, they could quickly move equipment from making consumer electronics to assembling wind turbines, saving about $1.2 million each year on new purchases. What's interesting is how adaptable this system proved to be. When expanding operations, workers needed only 60% of the usual training time compared to before, since many skills transferred directly between different production areas.

Measurable Gains in Productivity and Operational Efficiency

Data-Driven Improvements in Workshop Throughput and Cycle Times

Overhead crane systems today are making real improvements in productivity thanks to better material flow management and shorter handling times across facilities. According to research from McKinsey back in 2023, factories that implemented digital monitoring alongside their cranes saw throughput speeds jump anywhere from 17 to 24 percent simply because they cut down on those frustrating idle periods between operations. The ability to track loads in real time means less need for workers to manually coordinate everything, and when routes get automated, cycle times shrink since there's no wasting time moving things horizontally when it's not needed. Many plant managers report these changes make a world of difference in daily operations.

Productivity Case Study: Mid-Sized Automotive Assembly Plant Transformation

When a mid sized car plant installed those modular overhead cranes, they saw component transfer times drop dramatically from 48 down to just 29 minutes per chassis. What really made a difference was how these systems worked their magic with those smart speed controls and built in collision detection tech. Work stations could run flat out at around 92 percent capacity all day long without any hiccups or stoppages. That's actually about 34 percent better than what most plants manage when relying on old school forklift operations. And here's another plus: labor costs went down by roughly $127 per unit produced. Pretty impressive considering they still had to meet those strict ISO quality requirements that the whole industry lives by.

FAQs

What are the benefits of using overhead cranes compared to traditional methods?

Overhead cranes free up floor space, improve workflow continuity, enhance safety, and boost precision in load handling. They also integrate seamlessly into automated production systems and modern smart factory environments.

How do overhead cranes contribute to industry safety?

They reduce ground-level dangers by minimizing collision risks and come equipped with load limit sensors and emergency brakes. Additionally, remote control options allow materials to be handled safely from a distance.

Are overhead cranes suitable for all manufacturing layouts?

Yes, overhead cranes are adaptable to both compact and large-scale manufacturing layouts. They provide space-saving solutions and efficiency gains in various production settings.

How do overhead cranes integrate with smart factory systems?

Modern overhead cranes connect with manufacturing execution and warehouse management systems, enabling automatic adjustments to production needs and integration with other machines for seamless operations.

What advancements are expected in overhead crane technology?

Future trends include AI-driven routing and automation, enhanced collision avoidance, and wider integration with robotic systems for smarter production workflows.

Table of Contents

- Freeing Floor Space by Moving Material Handling Overhead Crane

- Reducing Congestion and Improving Workflow Continuity

- Comparative Benefits in Compact vs. Large-Scale Manufacturing Layouts

- Enhancing Safety and Precision in Heavy Load Handling

- Integrating Overhead Cranes into Modern, Automated Production Systems

- Flexibility and Scalability Across Diverse Manufacturing Applications

- Measurable Gains in Productivity and Operational Efficiency

-

FAQs

- What are the benefits of using overhead cranes compared to traditional methods?

- How do overhead cranes contribute to industry safety?

- Are overhead cranes suitable for all manufacturing layouts?

- How do overhead cranes integrate with smart factory systems?

- What advancements are expected in overhead crane technology?