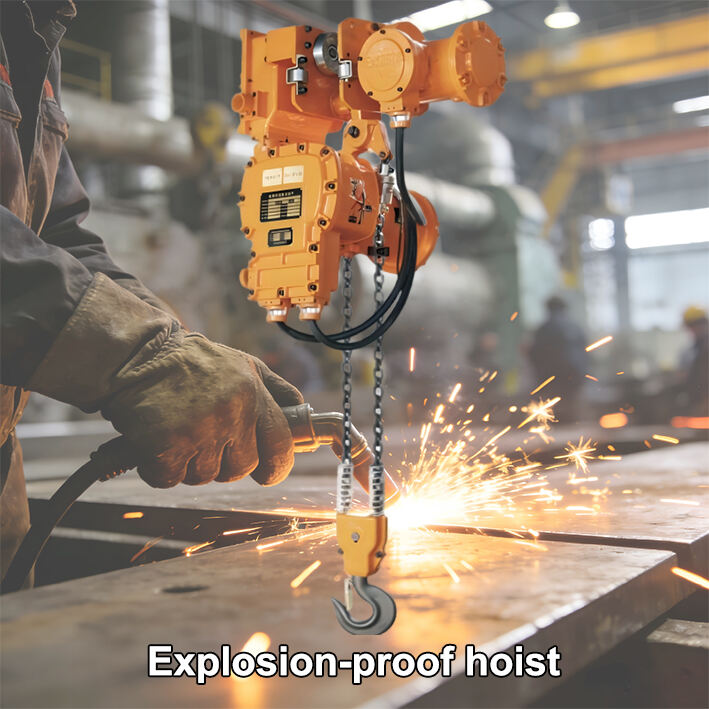

Standard crane hoists that operate flawlessly in conventional workshops may quickly become unsuitable for harsh environments such as chemical plants, marine environments, and metallurgical plants. Risks like metal corrosion, electrical spark ignition, and high-temperature failure constantly threaten production safety. Explosion-proof, corrosion-resistant, and high-temperature specialized hoists are lifting solutions designed to conquer these extreme conditions, their design and selection embodying profound scenario-based wisdom.

Key Design Features: Employs a fully enclosed explosion-proof casing. Even if internal electrical sparks or explosions occur, the robust casing prevents the leakage of flames and high-temperature gases, avoiding ignition of hazardous external environments. All mechanical components use non-sparking materials such as copper alloys. The braking system features heat insulation and rapid heat dissipation design.

Application Scenarios: Petrochemical plants, underground coal mines, grain processing workshops, and aluminum-magnesium powder production lines filled with dust.

Selection Considerations: Strict matching with the type of explosive (gas/dust), hazard level, and temperature group is essential. Certification marks (such as Ex d IIB T4 Gb) are an absolute prerequisite for safety compliance.

Corrosion-resistant hoists

Their design philosophy is to construct a three-in-one defense system of "materials, coating, and sealing."

Key design features: Structural components are made of stainless steel or hot-dip galvanized steel; wire ropes and chains are made of galvanized or stainless steel; the surface is coated with a heavy-duty anti-corrosion coating. All interfaces are equipped with high-level seals and moisture-proof breathing devices.

Application scenarios: Coastal ports, offshore platforms, electroplating and pickling workshops, sewage treatment plants, and chemical warehouses.

Selection points: Clearly define the type and concentration of corrosive media (saltwater, acid mist, alkali mist). For marine environments, a C4 (high) or C5-M (extremely high) corrosion resistance rating is typically required.

High-temperature hoists

The technical challenge lies in overcoming "thermal decay"—preventing insulation aging, lubrication failure, and material strength reduction.

Key design features: A high-efficiency heat insulation plate is installed between the hoist body and the hook. The motor uses H-class (180℃) or higher insulation materials and is often equipped with an independent forced air cooling or circulating water cooling system. Uses high-temperature steel wire ropes or chains, heat-resistant bearings, and molybdenum disulfide-based high-temperature grease.

Application Scenarios: Steel mill casting workshops, boiler room coal feeding areas, near glass melting furnaces, and cement plant clinker areas.

Selection Key Points: It is necessary to clearly define whether the environment is characterized by continuous high temperatures or intermittent heat radiation, and the precise peak temperature. Special consideration is required if the continuous operating temperature exceeds 40℃.

Selecting a special hoist is essentially a process of "translating operating parameters into equipment technical specifications." It is not simply an "enhanced version," but a precise protective engineering project based on physical and chemical principles. Investing in the right special hoist is investing in production continuity, equipment lifespan, and intrinsic safety in extreme environments. Thorough communication with professional suppliers regarding operating condition details and rigorous verification of their international/national certifications (such as ATEX, IECEx, and corrosion resistance rating ISO 12944) are crucial steps to ensure that the selected hoist can truly shoulder its responsibilities.

Hot News

Hot News2026-01-29

2026-01-27

2026-01-23

2026-01-22

2026-01-20

2026-01-16