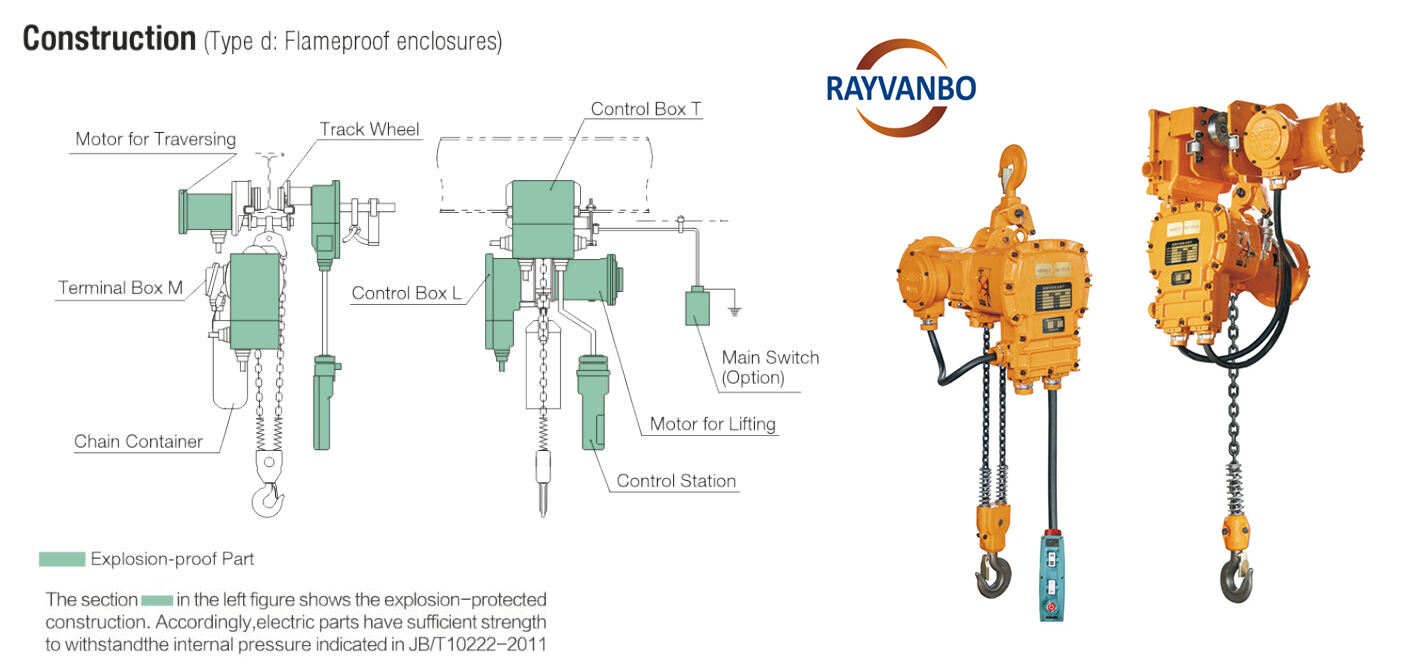

Product Name: Explosion-proof Electric Chain Hoist

Type: Hook type/ Electric trolley type

Lifting Capacity: 1-35ton

Lifting Height: 3/9m

Product Description

RAYVANBO's explosion-proof chain hoist is designed for flammable and explosive environments (such as petroleum, chemical, coal mines, etc.). It isolates electric sparks and flammable media through a fully sealed explosion-proof structure to ensure safe operation in high-risk scenarios such as gas and dust. It is suitable for harsh operations such as tank maintenance, underground equipment hoisting, and hazardous chemical handling, providing reliable lifting support for hazardous areas.

Product Parameters:

|

Power source |

200V(50/60Hz), 220V(60Hz),380V(50Hz), 400V(50Hz),415V(50Hz),440V(60Hz), 3 phase. Other voltaaes are available upon request. |

Operation voltage |

24/36/48V |

|

Operation method |

Pendant type push button cord (floor operation) (2-push-button-system for both hook suspension type and manual operated type trolley. 4-push-button-system for motorized frolley type.) |

Power supply method |

Cable power supply system |

Push button cord and power supply cable |

Rubber insulated flexible cable (3RNCT) |

Insulation of motor |

F class |

Braking system for lifting and lowering |

Pull-rotor motor brake |

Product Details:

Rayvanbo's explosion-proof electric chain hoist has the following advantages:

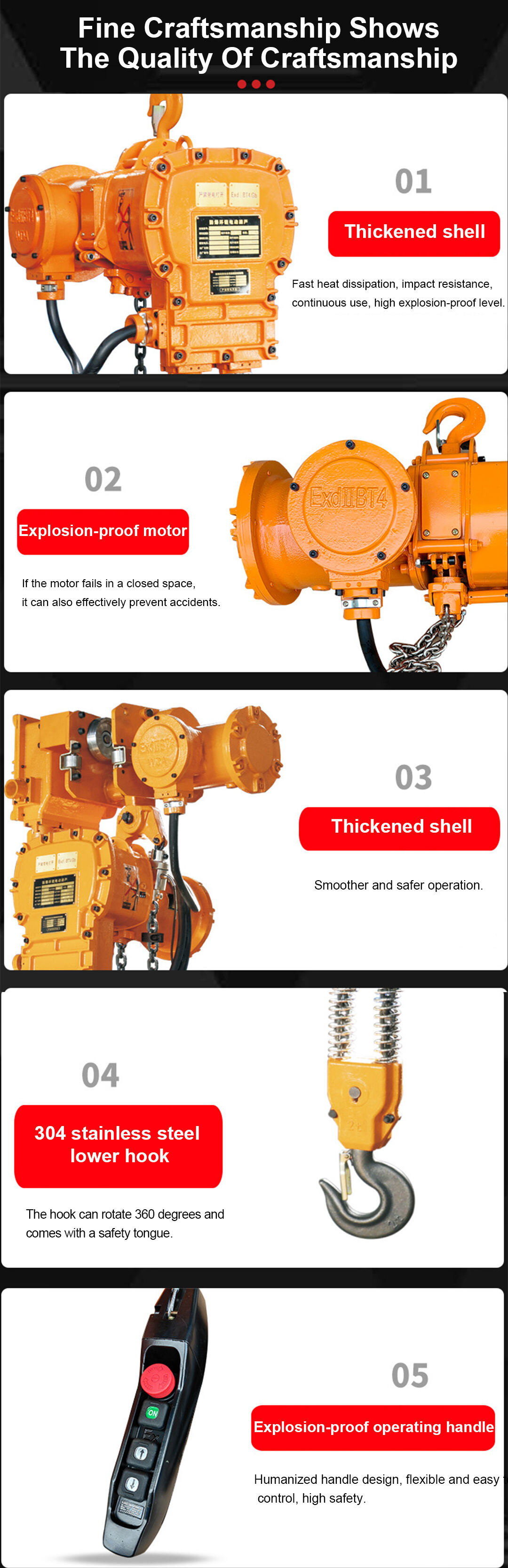

1. Sturdy explosion-proof shell

The thickened shell design has fast heat dissipation and impact resistance, does not get hot during long-term operation, and has more reliable explosion-proof performance.

2. Multiple protections for the motor

The explosion-proof motor has a built-in isolation structure, which can block sparks and avoid safety hazards when a sudden failure occurs in a confined space.

3. Flexible and safe hook

The stainless steel hook can rotate 360 degrees and has a built-in anti-drop lock. It automatically locks when the heavy object shakes to prevent accidental slipping.

4. Convenient operating handle

The explosion-proof handle has a clear button layout and can be easily operated even with gloves. The lifting speed can be freely adjusted and the response is sensitive.

The core design advantages of Rayvanbo explosion-proof electric chain hoist

1. Intrinsic safety and explosion-proof

The whole machine has passed the explosion-proof certification, and the motor, circuit and other key components adopt a fully enclosed explosion-proof design, which completely isolates the electric spark from the contact with the combustible medium, and ensures the safety of operations in flammable gas and dust environments.

2. High-strength and durable structure

The chain and hook are made of 304 stainless steel, which is corrosion-resistant and wear-resistant, and is suitable for harsh working conditions such as high temperature and humidity; the reinforced pulley block design reduces friction loss and extends the service life.

3. Flexible and precise control

The stepless speed control system, the lifting speed is smooth and adjustable, and the low-resistance guide wheel is used. The positioning accuracy of heavy objects is high, which is especially suitable for the installation of precision equipment or confined space operations.

At the same time, Rayvanbo explosion-proof chain electric hoist can cover multiple scenarios with differentiation

1. Energy and chemical industry

Oilfield derrick equipment maintenance, chemical plant reactor hoisting, explosion-proof performance without fear of oil and gas leakage risks.

Valve replacement in liquefied gas storage tank area to eliminate the hidden dangers of static sparks.

2. Mining and infrastructure projects

Transportation of underground support materials in coal mines, stable operation in humid and gassy environments.

Lifting of heavy machinery parts in tunnel construction, flexible steering in narrow spaces.

3. Special storage scenarios

Arrangement of shelves in hazardous chemical warehouses, explosion-proof design compatible with volatile gas environments.

Loading and unloading of flammable cargo containers at ports, coping with salt spray corrosion and high-intensity operation requirements.

Shipping & Packaging: