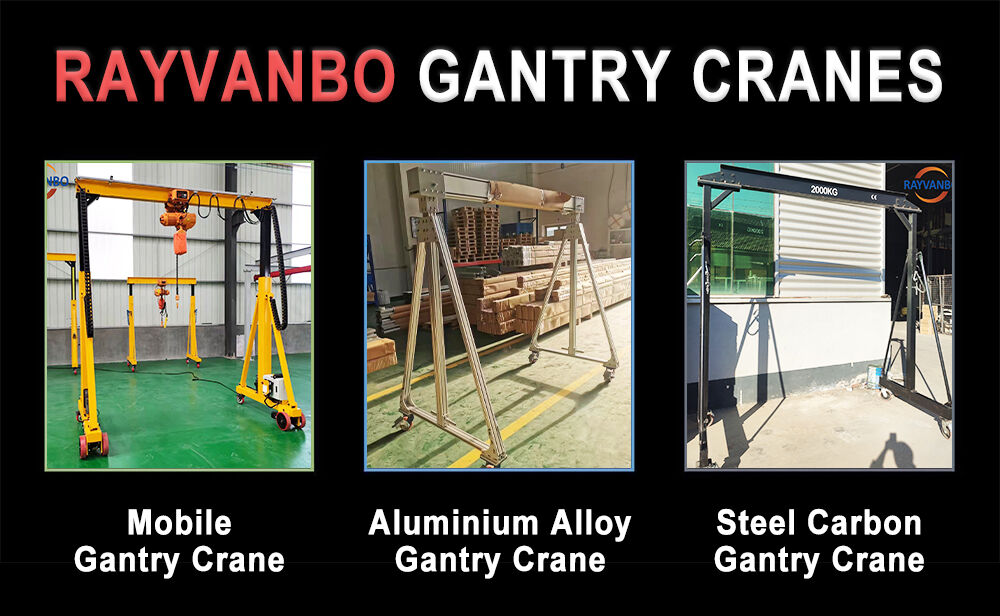

In modern industrial material handling, gantry cranes are widely used for lifting, moving, and positioning loads in workshops, warehouses, production facilities, and maintenance areas. Among light- to medium-duty lifting solutions, mobile gantry cranes, aluminium alloy gantry cranes, and steel carbon gantry cranes are three common choices for industrial buyers. Although all three belong to the gantry crane family, they differ significantly in structure, material, mobility, load capacity, and ideal application scenarios.

This comprehensive comparison of mobile gantry crane vs aluminium alloy gantry crane vs steel carbon gantry crane is designed to help engineers, procurement managers, and industrial buyers select the most suitable gantry crane system for their specific lifting requirements.

A mobile gantry crane is a freestanding lifting system consisting of two vertical legs and a horizontal beam, typically equipped with an electric chain hoist, manual hoist, or wire rope hoist. Mounted on wheels or lockable casters, mobile gantry cranes are designed for easy movement across different work areas, making them highly flexible industrial lifting solutions.

Mobile gantry cranes are widely used in warehouses, workshops, equipment maintenance areas, and temporary job sites. Their main advantage lies in mobility and fast deployment, as they do not require floor foundations or permanent installation. Many mobile gantry cranes feature adjustable height and span, allowing users to adapt the crane to various lifting tasks and workspace constraints.

From an SEO perspective, mobile gantry cranes are often searched as portable gantry crane, adjustable gantry crane, or movable gantry crane, reflecting their flexibility and ease of use in dynamic industrial environments.

An aluminium alloy gantry crane is a lightweight gantry crane system manufactured primarily from high-strength aluminium profiles. Compared with traditional steel gantry cranes, aluminium alloy gantry cranes offer significantly reduced weight while maintaining sufficient strength for light to medium lifting applications.

Aluminium alloy gantry cranes are especially popular in industries that require frequent relocation, manual handling of the crane structure, or use in clean environments. Common applications include laboratories, clean rooms, aerospace assembly, precision manufacturing, and maintenance tasks where corrosion resistance and portability are important.

Due to their lightweight design, aluminium alloy gantry cranes can often be assembled, disassembled, and transported by a single operator. This makes them ideal for users who need a portable gantry crane solution without relying on forklifts or heavy installation equipment.

A steel carbon gantry crane is a heavy-duty gantry crane system fabricated from carbon steel, designed to handle higher loads and more demanding industrial environments. Steel carbon gantry cranes are known for their high strength, rigidity, and durability, making them suitable for continuous and heavy-duty lifting operations.

These gantry cranes are commonly used in manufacturing plants, fabrication workshops, mold handling areas, and industrial warehouses where heavier loads and higher safety margins are required. Steel carbon gantry cranes can be either fixed or semi-mobile and are often equipped with electric hoists for efficient lifting.

From a buyer’s perspective, steel carbon gantry cranes are typically selected for long-term use, higher load capacities, and applications where structural strength and stability are more important than portability.

The most fundamental difference among these three gantry crane types lies in material selection and structural design. Mobile gantry cranes focus on mobility and adaptability, aluminium alloy gantry cranes emphasize lightweight construction and portability, while steel carbon gantry cranes prioritize strength and durability.

Aluminium alloy gantry cranes offer excellent corrosion resistance and ease of handling but are generally limited in load capacity compared to steel carbon gantry cranes. Steel carbon gantry cranes, on the other hand, provide superior load-bearing capability and long service life but require more effort for installation and relocation.

Mobile gantry cranes can be manufactured using either aluminium alloy or steel carbon materials, but their defining feature remains their wheeled, movable design rather than material alone.

Feature |

Mobile Gantry Crane |

Aluminium Alloy Gantry Crane |

Steel Carbon Gantry Crane |

Material |

Steel |

Aluminium alloy |

Carbon steel |

Mobility |

High, wheeled design |

Very high, lightweight |

Low to moderate |

Load Capacity |

Light to medium |

Light to medium |

Medium to heavy |

Portability |

Excellent |

Excellent |

Limited |

Durability |

Good |

Good |

Excellent |

Typical Applications |

Warehouses, maintenance |

Clean rooms, labs |

Factories, heavy workshops |

Cost Level |

Moderate |

Higher per unit |

Higher for heavy-duty |

Mobile gantry cranes are ideal for facilities that require flexible lifting across multiple workstations. They are commonly used for warehouse loading and unloading, equipment maintenance, mold handling, and temporary lifting tasks.

Aluminium alloy gantry cranes are best suited for applications where portability, corrosion resistance, and ease of handling are critical. Industries such as aerospace, electronics manufacturing, and clean room environments benefit greatly from their lightweight and non-corrosive properties.

Steel carbon gantry cranes excel in heavy-duty industrial environments where higher load capacity, rigidity, and long-term reliability are required. Typical applications include metal fabrication, machinery assembly, and industrial production lines.

In many factories, different gantry crane types are used together to create a flexible and efficient material handling system.

All gantry crane types must comply with industrial safety standards, but operational focus differs depending on the design. Mobile gantry cranes require proper caster locking and level floor conditions to prevent movement during lifting. Aluminium alloy gantry cranes require careful load control to stay within rated capacity limits. Steel carbon gantry cranes rely heavily on structural integrity, welding quality, and proper installation.

Routine inspection of hoists, lifting chains, hooks, fasteners, and structural components is essential for safe operation regardless of gantry crane type.

Choosing between a mobile gantry crane, aluminium alloy gantry crane, and steel carbon gantry crane depends on several factors, including load weight, lifting frequency, workspace layout, and mobility requirements.

If your operation requires frequent relocation and flexible lifting, a mobile gantry crane offers the best balance of versatility and cost. If portability and lightweight handling are priorities, an aluminium alloy gantry crane is an excellent solution. For heavy-duty, long-term industrial lifting, a steel carbon gantry crane provides unmatched strength and stability.

For small to medium workshops seeking flexible lifting solutions with minimal installation cost, mobile gantry cranes and aluminium alloy gantry cranes offer excellent value. For industrial buyers focused on durability, higher load capacity, and long service life, steel carbon gantry cranes represent a reliable long-term investment.

Customized gantry crane solutions can further optimize efficiency and safety for specific applications.

Which gantry crane is the most portable?

Aluminium alloy gantry cranes are the most portable due to their lightweight structure, followed closely by mobile gantry cranes.

Which gantry crane can handle the heaviest loads?

Steel carbon gantry cranes are best suited for heavy-duty lifting applications.

Can all gantry cranes be equipped with electric hoists?

Yes, all three types can be equipped with electric chain hoists or wire rope hoists.

Are mobile gantry cranes suitable for permanent use?

Yes, they can be used long-term, but they are best suited for flexible or changing work environments.

Which gantry crane has the lowest installation cost?

Mobile gantry cranes typically have the lowest installation cost since no foundation is required.

Mobile gantry cranes, aluminium alloy gantry cranes, and steel carbon gantry cranes each serve distinct roles in industrial material handling. Understanding their differences in material, mobility, load capacity, and application helps buyers make informed decisions. With proper selection and maintenance, any of these gantry crane systems can significantly enhance productivity, safety, and operational efficiency.

Hot News

Hot News2026-01-29

2026-01-27

2026-01-23

2026-01-22

2026-01-20

2026-01-16