An overhead crane, is one of the most widely used material handling systems in industrial facilities. It is designed to lift, move, and position heavy loads within a fixed working area by traveling on elevated runway rails installed on building columns or steel structures. Compared with floor-mounted lifting equipment, overhead cranes make full use of vertical space, allowing factories and warehouses to handle heavy materials efficiently without occupying valuable ground area.

Understanding the overhead crane working principle is essential for users, engineers, and buyers. It not only helps ensure correct equipment selection and safe operation, but also improves production efficiency, reduces labor intensity, and extends equipment service life in long-term industrial use.

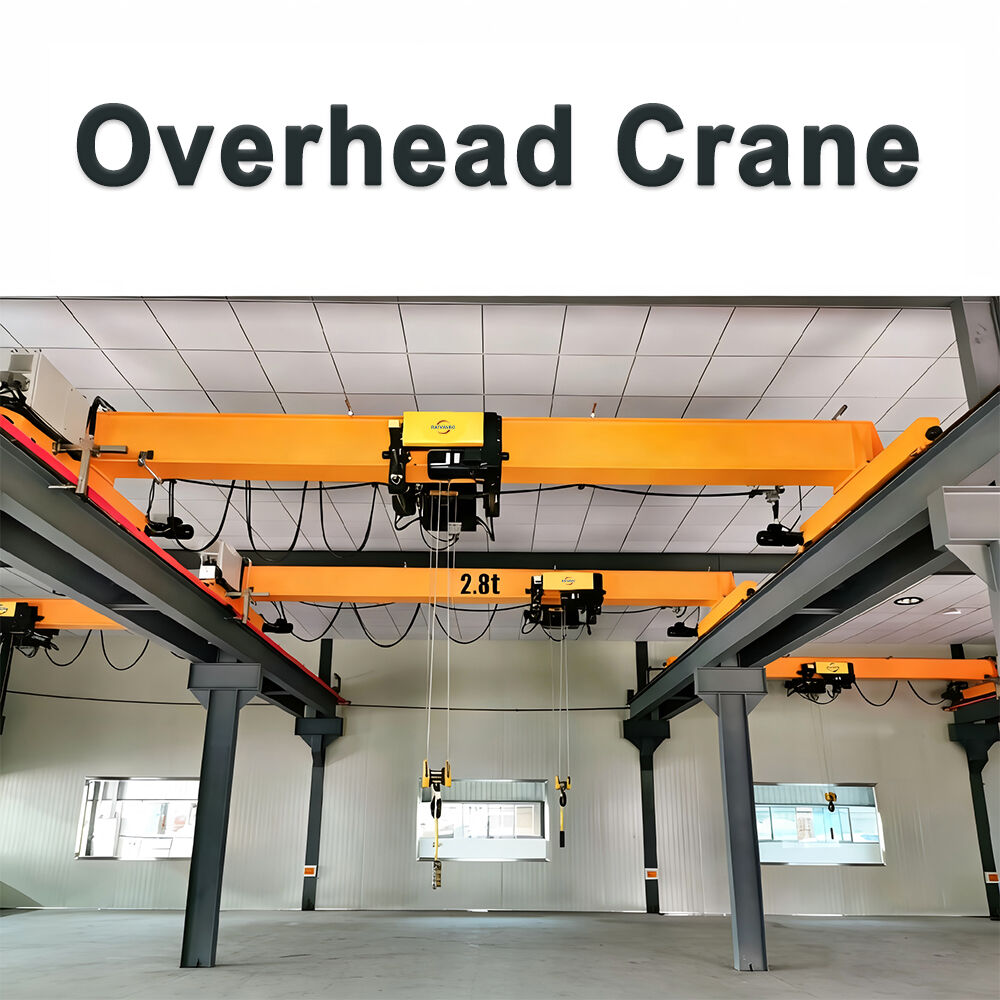

The working principle of an overhead crane is based on the coordinated operation of several core components. The bridge girder forms the main load-bearing structure and spans the width of the working area. End carriages are mounted at both ends of the bridge girder and allow the crane to travel longitudinally along the runway rails. Installed on the bridge girder is the trolley, which carries the hoist and enables horizontal movement across the crane span.

The hoist is the key lifting mechanism responsible for raising and lowering loads vertically. Depending on the application, it may be an electric chain hoist or a wire rope hoist. The entire system is controlled by an electrical control unit, which can be operated through a pendant control, wireless remote control, or operator cabin. All these components work together to ensure stable, precise, and safe lifting operations.

The working principle of an overhead crane relies on the combination of three fundamental motions: hoisting motion, cross travel motion, and long travel motion. The hoisting motion allows the load to be lifted or lowered vertically through the hoist motor and braking system. The cross travel motion enables the trolley and hoist to move horizontally along the bridge girder, positioning the load across the width of the working area. The long travel motion allows the entire crane bridge to move along the runway rails, transporting the load along the length of the workshop or warehouse.

By coordinating these three motions, an overhead crane can accurately position loads at almost any point within its operating range. This three-dimensional movement capability is what makes overhead cranes highly efficient for industrial material handling.

Most overhead cranes are powered by electric motors and controlled through advanced electrical systems. The control system regulates speed, direction, acceleration, and braking to ensure smooth and precise operation. Modern overhead cranes are often equipped with variable frequency drives (VFDs), which improve motion control and reduce mechanical stress.

Safety devices play a critical role in the working principle of overhead cranes. These include overload protection systems, upper and lower limit switches, emergency stop buttons, anti-collision systems, and thermal protection for motors. Together, these features significantly reduce operational risks and improve overall workplace safety.

The overhead crane working principle offers multiple advantages for industrial users. By utilizing overhead space, cranes improve floor efficiency and workflow organization. Their stable structure allows for high lifting capacities and continuous operation, making them suitable for demanding industrial environments. Precise positioning reduces handling errors, while automated and remote control options enhance operator safety and productivity.

These advantages explain why overhead bridge cranes are essential equipment in manufacturing plants, heavy industry, logistics centers, and assembly lines worldwide.

Overhead cranes are commonly used in steel plants, machinery manufacturing, automotive production, warehouses, power stations, and heavy equipment assembly workshops. Their reliable working principle supports the lifting of raw materials, components, finished products, and heavy machinery parts. In modern smart factories, overhead cranes are increasingly integrated with automated production systems to further improve efficiency.

Selecting the right overhead crane requires careful consideration of lifting capacity, span, lifting height, duty class, control method, and operating environment. Factors such as temperature, humidity, dust, and corrosion conditions should also be evaluated. Working with an experienced overhead crane manufacturer ensures proper design, compliance with standards, and long-term operational reliability.

Looking for a high-quality overhead crane or overhead bridge crane for your factory or warehouse?

We provide customized crane solutions with professional engineering support, reliable quality, and competitive pricing.

Hot News

Hot News2026-01-29

2026-01-27

2026-01-23

2026-01-22

2026-01-20

2026-01-16