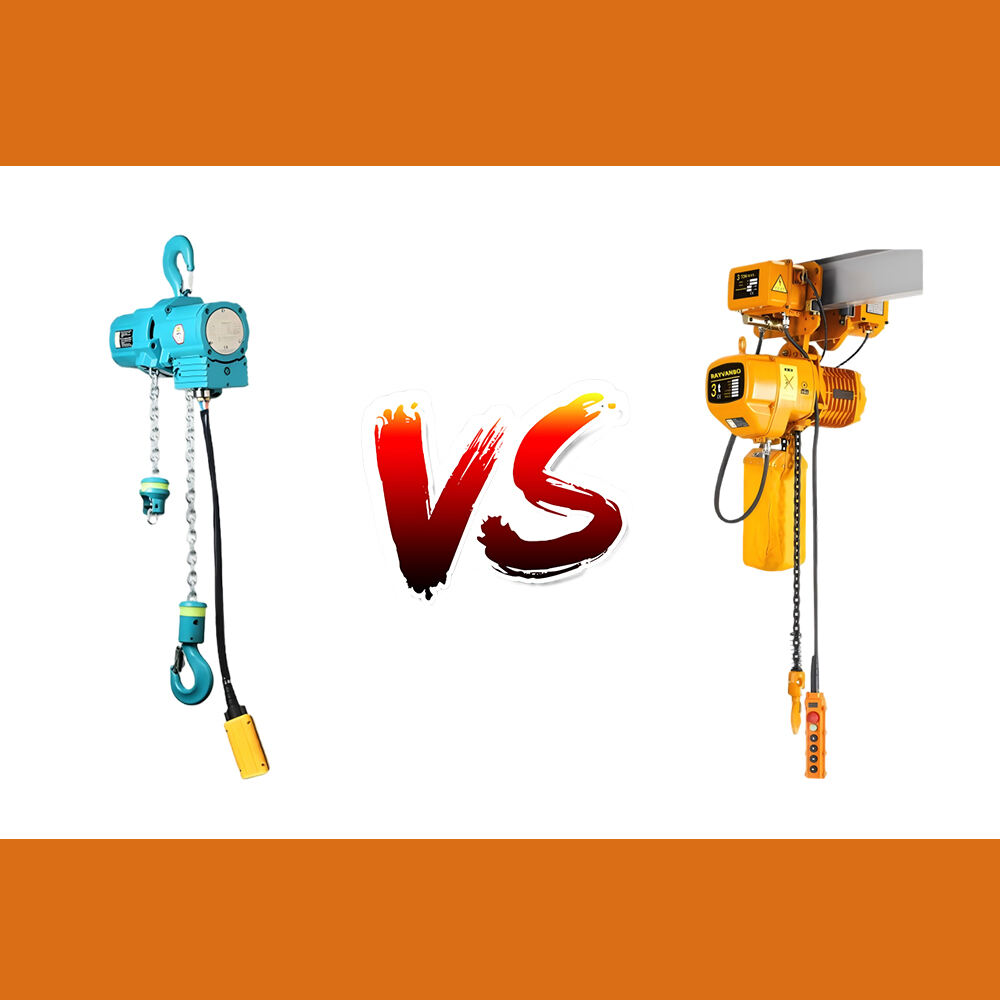

In the industrial lifting field, pneumatic hoists and HHBB electric hoists are both commonly used devices. However, due to their different power principles and design features, their applicable scenarios and performance also differ significantly:

1. Power and Safety Attributes

Pneumatic hoists use air as their primary power source. The air-driven motor drives internal components to lift heavy objects, eliminating the need for electrical power and providing enhanced explosion-proof performance. During operation, no sparks are generated, and the hoist itself lacks a power supply. This reduces the risk of electrical fires and electric shock in flammable, explosive, or dusty environments, such as the petroleum, chemical, and coal mining industries. HHBB electric hoists rely on electricity to lift heavy objects, using a 220V power supply or a 380V industrial power supply. The motor is prone to sparking, requiring additional explosion-proof equipment for use in hazardous environments, posing a safety hazard.

2. Applicable Environment and Durability

Pneumatic hoists have a relatively simple structure and lack complex electrical components. They are resistant to high and low temperatures (-20°C to 80°C) and moisture and corrosion, allowing them to operate reliably even in rainy, snowy weather or in high-humidity workshops. HHBB electric hoists, however, are limited by electrical components such as motors and wiring, and have higher requirements for ambient temperature, humidity, and dust content. Humid or dusty environments can easily lead to wiring short circuits and motor damage.

3. Control and Performance Characteristics

Pneumatic hoists control lifting speed and traction by adjusting air pressure, resulting in smoother speed regulation and the ability to perform frequent starts and stops, as well as inching operations. They are suitable for applications requiring precise control, such as precision assembly. HHBB electric hoists generally have fixed-gear speed regulation and experience greater inertia during starts and stops. They are more suitable for general lifting operations where speed accuracy is less critical. However, they offer a wider range of rated loads (some reaching tens of tons) and higher single-lift efficiency.

4.Maintenance and Cost Differences:

Pneumatic hoists lack easily damaged electrical components like motors and circuit boards. Daily maintenance requires only cleaning the air passages and adding lubricating oil, making maintenance simple and cost-effective. HHBB electric hoists, on the other hand, require regular inspections of the motor, wiring, and brake system. Repair and replacement costs for these components are high, resulting in higher overall O&M costs than pneumatic hoists.

Hot News

Hot News2026-01-29

2026-01-27

2026-01-23

2026-01-22

2026-01-20

2026-01-16