Product Name:European Type Electric Chain Hoist

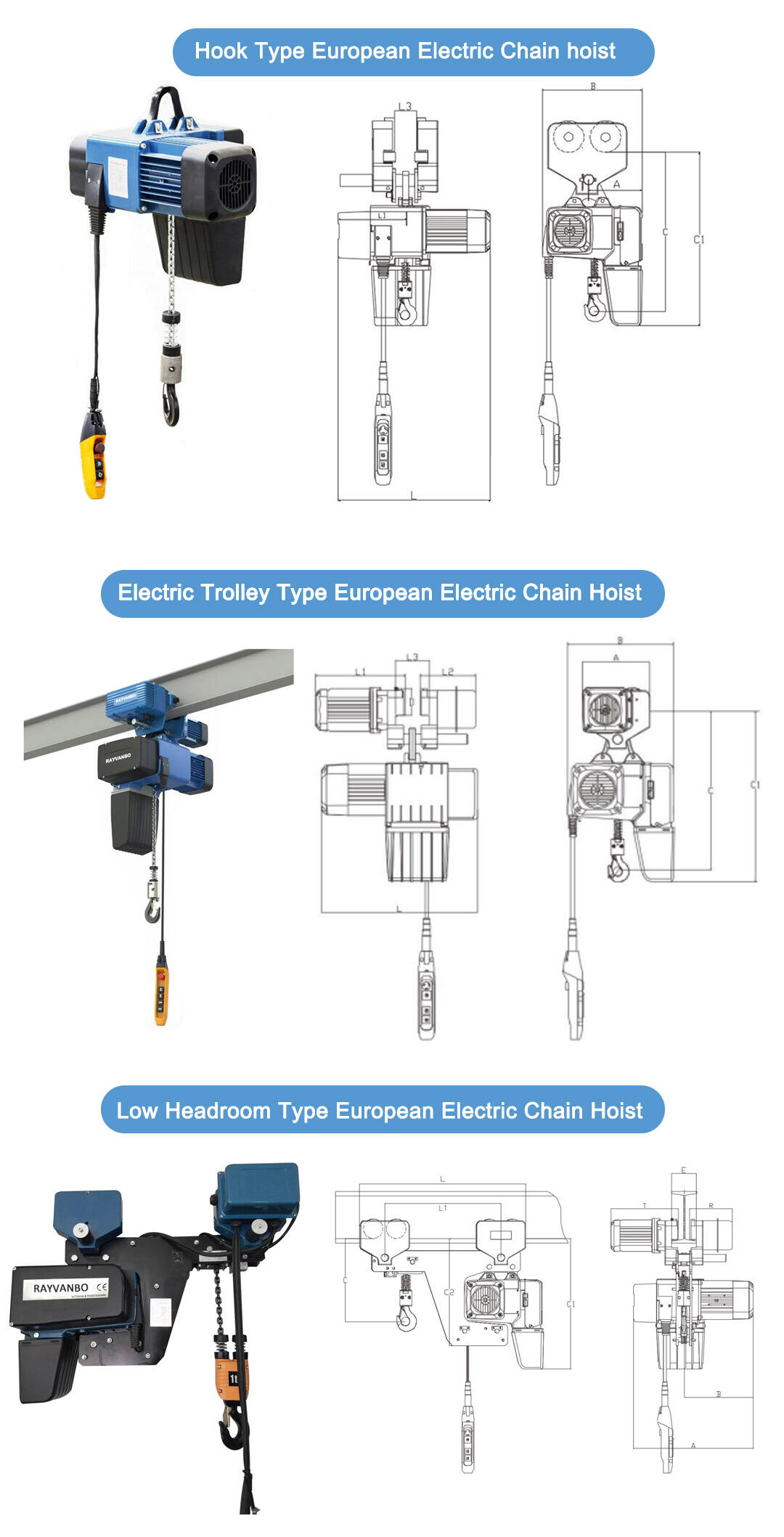

Model: HH

Type: Fixed type / Manual trolley type/ Electric trolley type/Low headroom type/Double hook type

Lifting Capacity:125kg--2t (can be customized)

Lifting Height: 3-12m (can be customized)

Product Description

Electric fixed type

Suitable for high-frequency fixed-point operation scenarios (such as fixed workstations on production lines and fixed-point hoisting in warehouses). It adopts an integrated body design, which is easy to install and stable in operation. Equipped with a variable speed motor, it covers the load requirements of 0.125T-2T; the shell takes into account both heat dissipation and durability, and the high-strength chain treated with a special anti-rust process extends the service life. The handle design fits the operating habits and improves the control accuracy.

Electric operation type

Designed for dynamic multi-station scenarios (such as workshop material transfer and cross-regional collaboration), it is equipped with an electric trolley or track system to achieve horizontal free movement and greatly expand the scope of operation. The independently controlled motor and walking mechanism respond quickly and accurately position to meet flexible and efficient industrial needs.

Product Parameters:

|

Model |

Lifting Capacity(KG) |

Lifting Speed (n/min) |

Motor Power(KW) |

Rotation Speed (r/min) |

Operating Voltage (V) |

Control Voltage (V) |

Work Duty (FEM/ISO) |

HH0.125-01 |

125 |

8/2 |

0.4/0.1 |

2880/720 |

220-460 |

24 |

2M/M5 |

HH0.25-01 |

250 |

8/2 |

0.4/0.1 |

2880/720 |

220-460 |

24 |

2M/M5 |

HH0.5-01 |

500 |

8/2 |

0.75/0.2 |

2880/720 |

220-460 |

24 |

2M/M5 |

HH0.5-02 |

500 |

4/1 |

0.75/0.2 |

2880/720 |

220-460 |

24 |

2M/M5 |

HH01-01 |

1000 |

8/2 |

1.5/0.37 |

2880/720 |

220-460 |

24 |

2M/M5 |

HH01-02 |

1000 |

4/1 |

0.75/0.2 |

2880/720 |

220-460 |

24 |

2M/M5 |

HH02-02 |

2000 |

4/1 |

1.5/0.37 |

2880/720 |

220-460 |

24 |

2M/M5 |

Product Details:

Rayvanbo's European chain hoist products have the following advantages in details:

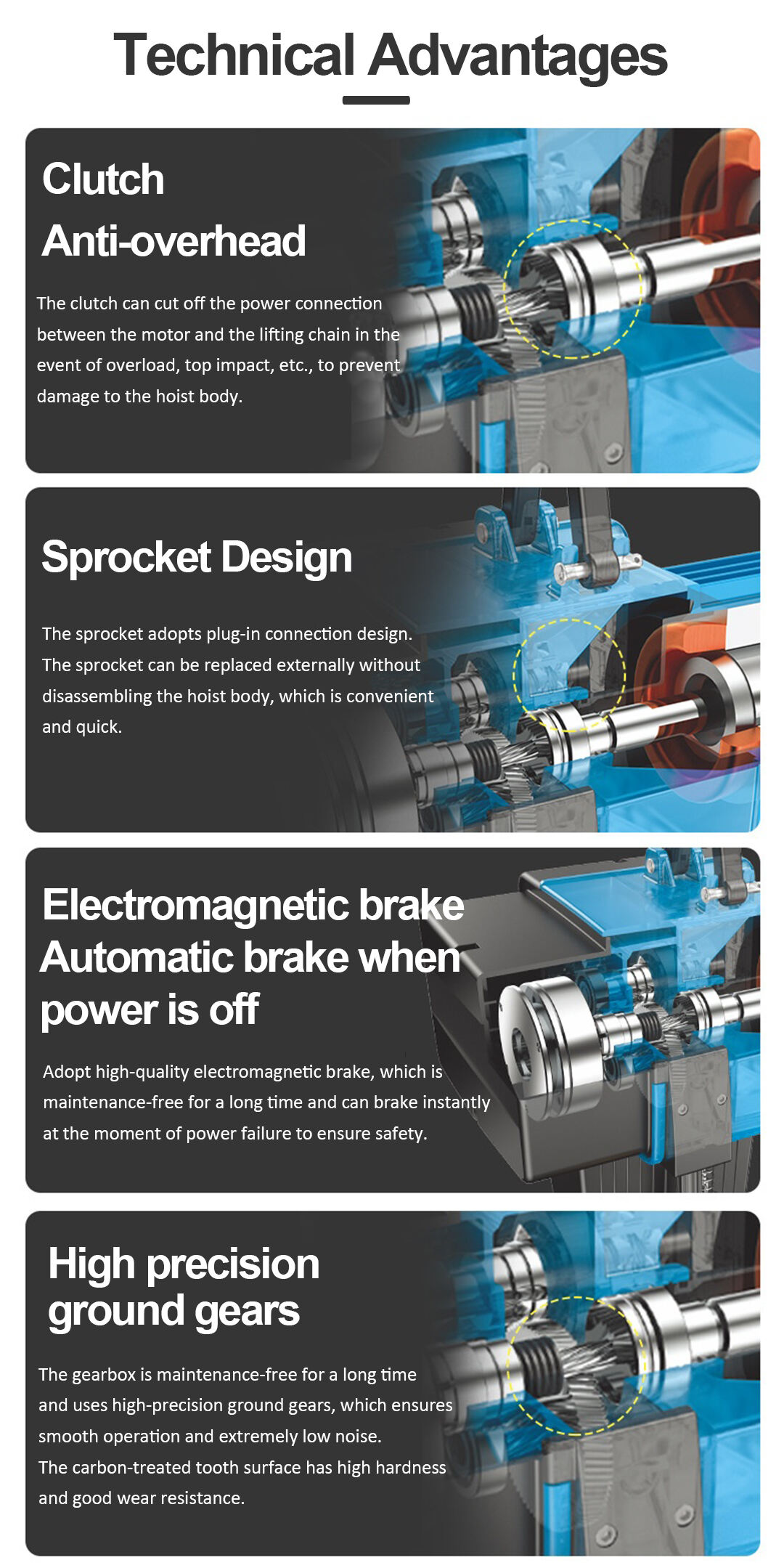

1. Overload protection device

When the load exceeds the rated range or an unexpected impact occurs, the power connection between the motor and the chain is automatically cut off to avoid damage to the internal structure of the equipment.

2. Modular sprocket design

The sprocket adopts an external replaceable structure, which can be quickly replaced without disassembling the whole machine, greatly reducing maintenance time and operation difficulty.

3. Automatic locking when power is off

Equipped with a high-performance electromagnetic braking system, the brake is immediately triggered at the moment of power failure to ensure the safety of the lifting operation and long-term stable and reliable use.

4. Silent and wear-resistant transmission

The gears are processed by precision grinding technology, running smoothly and with extremely low noise, which can extend the service life.

In addition to the above hoist details, our hoist also has the following structural advantages:

1. Low-voltage safety control handle

The handle adopts ergonomic design, comfortable to hold, and equipped with a 5V low-voltage control system, which is sensitive to operation and effectively ensures the safety of personnel's electricity use.

2. Forged reinforced hook

Through alloy steel forging and precision heat treatment process, the overall strength of the hook is greatly improved to ensure stable load-bearing capacity under high-load scenarios.

3. Anti-corrosion high-strength lifting chain

The surface of the chain is galvanized for strong corrosion resistance, and the carburizing process is used to improve toughness and impact resistance, adapting to a variety of complex working environments.

Shipping & Packaging: