Çfarë janë Liftuer Magnetik Përhershëm si? Përcaktimi i përbërësve kryesorë

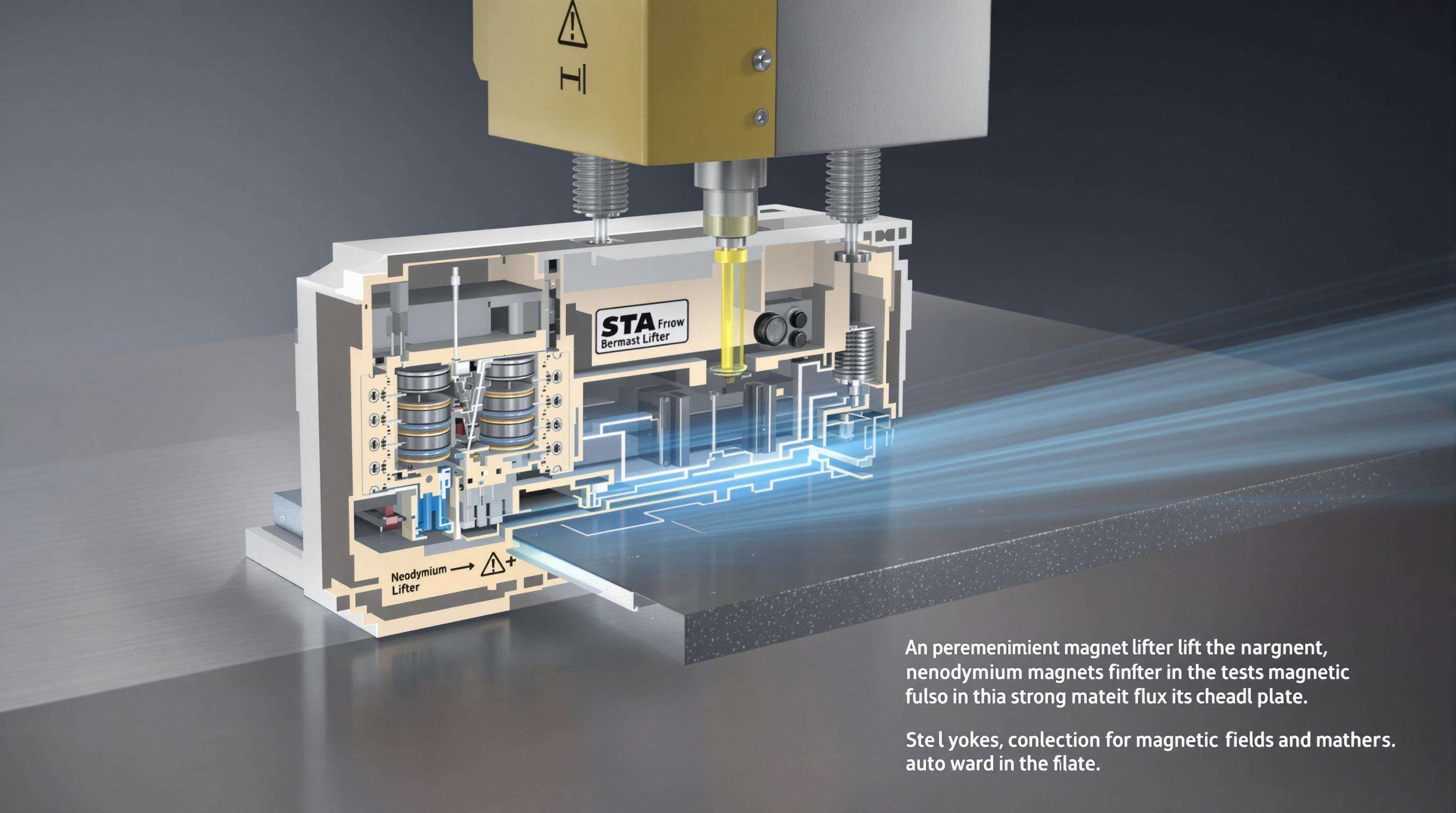

Ngarkuesit me magnet të përhershëm (PML) janë pajisje ngarkimi sipërfaqësorë që punojnë duke përdorur qarqe magnetike të integruara në bazë për të mbajtur sipërfaqet ferrose. Elementët kryesorë përfshijnë zakonisht magnete me performancë të lartë të bazuar në NdFeB të radhitura në strukturë me polaritet të ndryshueshëm, copëza çeliku për të udhëzuar dhe përqendruar fluksin magnetik dhe një mbështjellës jo magnetik për të mbrojtur nga streset mekanike (zakonisht prej çeliku të pakorodhur ose alumini).

Spre ndryshe nga magnetët e përkohshëm, PML-ja zhvillon një fushë 300-500 Gauss për shkak të alinimit të dominave magnetike të brendshme. Ata aktivizohen nga levere manuale ose butonë shtypi ose në mënyrë të largët nga pajisjet e pilotit. Kjo strukturë lejon ngritjen e ngarkesës deri në 1000 kg pllakash çeliku, pjesë makinerie etj., pa nevojën e energjisë hidraulike ose elektrike.

Konsideratat kyçe inxhinierike përfshijnë integritetin e kontaktit të sipërfaqes për transfer optimal të fluksit dhe përshtatshmërinë e materialeve - që kërkon sipërfaqe të rrafshta, ferike të papara për kapacitetet e renditura.

Liftuer Magnetik Përhershëm shkenca e Generimit të Fluksit Magnetik

Ngarkuesit me magnet të përhershëm i rregullojnë magnettë në një model dhe përdorin magnettët e aligjuar ferrous ose neodymium për të fokusuar forcën e ngritjes mbi materialin ferrous që duhet lëvizur. Fusha magnetike intensive përfshin thellë nën sipërfaqe për të ngritur dhe transportuar objekte. Magnettët e yokes njihen edhe si magneta të "mbajtjes së ngarkesës" dhe nuk kërkojnë energji për të mbajtur një ngarkesë, duke i bërë të përshtatshëm për aplikime të ndjeshme ndaj energjisë. Magnetizmi nga qarku i tyre magnetik tërheq linjat e fluksit në pjesët ferromagnetike, duke ofruar 10× forcën e tërheqjes së peshës së pajisjes.

I përhershëm vs. Formimi i fushës elektromagnetike

Modelet e përhershme mbajnë 300-500 Gauss fushat pafundësisht përmes aliazheve të rralla të sintetizuara, duke eliminuar koston e energjisë dhe rreziqet e humbjes së energjisë. Elektromagnetet kërkojnë energji të vazhdueshme (1.2–3 kW/orë) për të mbajtur nivele të krahasueshme të fluksit, por ofrojnë fortësi të rregullueshme të fushës.

Qarqet e mbyllura vs. të hapura

Qarqet me unaza të mbyllura arrijnë 95% efikasitet fluksi duke udhëzuar linjat magnetike nëpër pjesën e punës dhe më pas në pajisjen ngjyrosëse. Konfigurimet e hapura humbasin 30–40% të forcës së tërheqjes për shkak të shpërndarjes në hapësirën ajrore. Për pllakat e çelikut me trashësi 1", sistemet e mbyllura ofrojnë 9.8 kN forcë të mbajtjes në krahasim me 5.9 kN në konfigurimet e hapura.

Zgjedhja e Materialeve: Elemente të Rëndësishme për Përputhshmërinë

Ngarkesa eftektive kërkon pjesë të punës me:

- Përshkallëshmëri ≥ 100 μH/m (çelik karboni standard)

- Trashësia minimale që përputhet me specifikimet e lifterit

- Sheshtësia e sipërfaqes brenda tolerancë 0.002"

Materialet e papërshtatshme (p.sh., alumini, shumica e çelikut të pakorodhshëm) zvogëlojnë ngjitjen nga 60–75% për shkak të rrjedhjes së flukseve.

Mekanizmat e Aktivizimit/Deaktivizimit në Liftuer Magnetik Përhershëm s

Sistemet e Levës Rrotulluese

Leverat rotative i drejtojnë sërish rrugët e fluksit të brendshëm në 2–3 sekonda , duke i përshtatur magneteve në një konfigurim me qark të mbyllur. Veprimi mekanik kërkon vetëm 15–20 paund forcë (OSHA 2023) , duke lejuar manipulimin me cikle të larta pa energji elektrike.

Funksione Sigurie me Çelës

Çelësat me dy faza parandalojnë lëshimin e rastësishëm:

- I parë reziston vibracioneve deri në 5g

- Pins të dyfishtë me çelës të varur nën presion tërheqin nëse ndodh lëvizje e papritur

Studimet tregojnë se këto i zvogëlojnë incidentet e rënies së ngarkesës nga 60% (raporti i Sigurisë për Ekipet Ngjitëse 2024 ).

Dinamika e Kontaktit Sipërfaqësor (Tolerancë 0.002")

Zvogëlimi i ngjithjes magnetike 30–40% në sipërfaqe që e tejkalojnë 0.002" jo uniformiteti (ANSI/ASME B30.20-2022). Për sipërfaqe të lëmuara apo të kanalizuara, shufër ferromagnetike rikthejnë integritetin e kontaktit.

Liftuer Magnetik Përhershëm t në Aplikimet Industriale

Prodhimi i Çelikut

Mangjalat 3/4" trashësi pllakësh me një margina e sigurisë 10:1 —kritike për çelik të rregullt ose të oksiduar. Rezistenca ndaj ndërprerjeve të energjisë elektrike zvogëlon rënien e pllakave me 73% kundër klipeve manuale.

Montimi i Automjeteve

Transferon blloqe motori 500kg në qelula robotike me saktësi ±2mm . Veprim pa energji i shmang pengesat elektromagnetike, duke i kursyer kohë cikli me 22% kundër kapëseve vakuumi.

Ndërtimi i kuqeve

Modelet e klasës marine (me shtëpi të prej çeliku të pakorrueshëm, me pjesë të brendshme të plakuara me nikel) mbajnë 98% dendësi fluksi nË 95% lagështie . Frekuenca e mirëmbajtjes zvogëlohet 40% krahasuar me lifterët e zakonshëm në ambiente me ujë të kripur.

Protokolle Sigurie për Ngarkuesit me magnet të përhershëm

Llogaritja e Kapaciteteve të Ngarkimit

Përdorni formulën:

Kapaciteti i Sigurtë = (Vlerësimi i Lifterit) × (Faktori i Trashësisë së Materialit) × (Koeficienti i Rrafshësisë së Sipërfaqes)

Aplikoni një margjinë sigurie 3:1 për ngarkesa goditëse.

Verifikimi Manual në Sistemet e Automatizuara

Kontrollot para ngarkesës sigurojnë:

- Përdorimi i forcës magnetike në qendër të gravitetit të ngarkesës

- Aktivizimi i dëgjueshëm i palës

- Asnjë shtresë joferrike apo pluhur

Inspektimi me sy të lirë zbulon parregullsi më të vogla se 0,002" të anashkaluara nga sensorët.

Ngarkuesit e Përhershëm kundër Ngarkuesve Elektromagnetikë: Krahasim Operacional

Efikasiteti Energjik

Përhershëm: Konsum zero energjie në mbajtje pasive.

Elektromagnetike: 1,2–3 kW/orë , duke kushtuar 25.000+ dollarë/vit për 20+ njësi.

Needa për Mirëmbajtje

Përhershëm: Lubrifikim dy herë në vit ; pllakat e amortizimit zgjasin 50.000+ cikle .

Magnetike: Kontroll i bobinave çdo tremujor; $800–$1,200 zëvendësime cdo 8,000–12,000 orë .

Sistemet e përhershme zvogëlojnë kohën e pushuar nga puna për 23 orë në vit në fabrikat automatike.

Pyetje të shpeshta mbi Ngarkuesit me magnet të përhershëm

Cilat janë përbërësit kryesorë të ngarkuesve magnetikë të përhershëm?

Ngarkuesit magnetikë të përhershëm përbëhen nga magnete NdFeB me performancë të lartë, copëza çeliku për udhëzim të fluksit magnetik dhe një mbështjellës jo magnetik për mbrojtje nga stresi mekanik.

Si ndryshojnë ngarkuesit magnetikë e përhershëm nga ngarkuesit elektromagnetik?

Ngarkuesit me magnet të përhershëm nuk përdorin energji dhe mbajnë një fushë magnetike të qëndrueshme, ndërsa ngarkuesit elektromagnetikë kërkojnë energji të vazhdueshme dhe ofrojnë rregullim të fortësisë së fushës.

Cilat janë karakteristikat e sigurisë të ngarkuesve me magnet të përhershëm?

Ngarkuesit me magnet të përhershëm kanë mbylesë dyfishe që i rezistojnë vibracioneve dhe parandalojnë çlirimin e rastësishëm, gjë që mund të zvogëlojë ndjeshëm incidentet me humbje ngarkese.

Në cilat industri përdoren zakonisht ngarkuesit me magnet të përhershëm?

Ngarkuesit me magnet të përhershëm përdoren zakonisht në prodhimin e çelikut, montimin automobilistik dhe ndërtimin e anijeve për shkak të besueshmërisë dhe efikasitetit të tyre.

Përmbajtja

- Çfarë janë Liftuer Magnetik Përhershëm si? Përcaktimi i përbërësve kryesorë

- Liftuer Magnetik Përhershëm shkenca e Generimit të Fluksit Magnetik

- Mekanizmat e Aktivizimit/Deaktivizimit në Liftuer Magnetik Përhershëm s

- Liftuer Magnetik Përhershëm t në Aplikimet Industriale

- Protokolle Sigurie për Ngarkuesit me magnet të përhershëm

- Ngarkuesit e Përhershëm kundër Ngarkuesve Elektromagnetikë: Krahasim Operacional

- Pyetje të shpeshta mbi Ngarkuesit me magnet të përhershëm