1. Exceptional Load Handling Capabilities of European Type Electric Wire Rope Hoists

Superior Load Capacity for Heavy-Duty Applications

European electric wire rope hoists handle serious weight loads, often going up to 5 tons or even more, which makes them perfect for tough industrial jobs where things get really heavy. Built tough from the ground up, these machines last through rough conditions without breaking down. The materials used have gotten better over time, so now they come with strong steel cables that let them carry more weight without adding extra bulk. Industry reports show that when a hoist can lift heavier stuff, factories need fewer trips to move big loads around, saving both time and money. What's great is how adaptable these hoists actually are. Companies can tweak them for their particular needs, whether it's special ways to attach loads or custom rigging setups. This kind of flexibility means businesses can fit the equipment right into their existing workflows instead of forcing operations to conform to standard hoist designs.

Versatility in Handling 5 Ton and Beyond

Electric wire rope hoists are highly adaptable machines that manufacturers and builders rely on for countless tasks. They work well in everything from factory floors to towering construction projects. These hoists can lift over 5 tons at once, which means they're essential when moving big items like steel beams or parts of heavy machinery around job sites. Construction crews have seen firsthand how these devices streamline operations on large scale projects where materials need to be moved frequently between locations. The European type models especially stand out because businesses don't need separate equipment for different weight requirements anymore. A single unit handles multiple load sizes, cutting down costs and storage space needed. What makes these hoists particularly valuable is their ability to connect with various power systems found throughout different industries, giving operators real flexibility no matter what kind of facility they're working in.

For these reasons, investing in an European Type Electric Wire Rope Hoist with robust load handling capabilities is a prudent choice for enhancing productivity and meeting diverse industrial needs.

2. Compact Design and Space Efficiency

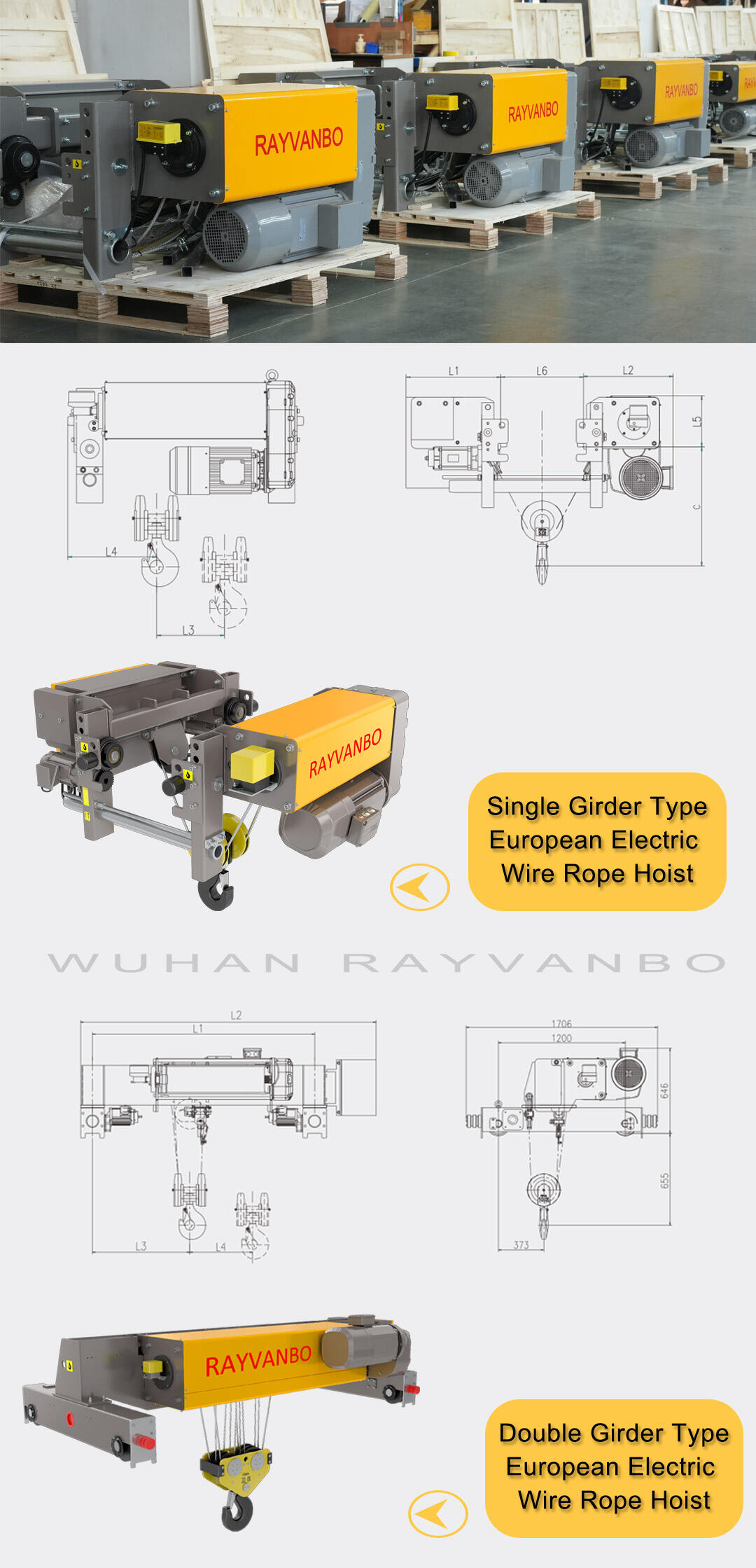

European-Type Design for Seamless Integration

The European Type Electric Wire Rope Hoist stands out because of its small footprint, making it easy to fit into current factory layouts without major modifications. The compact size really matters in tight spaces like storage areas and production floors where every inch counts. What's great is these units actually work with older overhead cranes already in place, so companies don't have to tear everything down and start fresh. Plant supervisors report that when they manage space better with these hoists, operations run smoother and workers follow safety protocols more consistently. Recent improvements in construction materials have led to lighter versions too. This means less strain on building structures and lower expenses during setup. For manufacturers looking to boost productivity without breaking the bank, these updated models represent a smart investment choice.

Applications in Confined Industrial Spaces

Electric wire rope hoists come in a compact package that works great in tight industrial spaces such as shipyards and smaller warehouses where getting around stuff matters a lot. The way these hoists are built lets workers make better use of available floor area so they don't have to sacrifice safety just to fit everything in. We've seen them put to work during maintenance jobs in places where there simply isn't room for bigger machinery. These little powerhouses handle complex lifts even when space gets really cramped, which means more gets done faster and workers stay safer too. Plus, they're built tough enough to handle rough conditions on site, so breakdowns happen less often and operations keep running smoothly day after day.

3. Advanced Safety Mechanisms for Risk Mitigation

Emergency Stop and Overload Protection Systems

Worker safety matters a lot in factories and warehouses, which is why European electric wire rope hoists come packed with built-in safeguards. Most models have emergency stop buttons right where operators need them, so they can shut things down fast if something goes wrong. This simple feature cuts accident risks dramatically when unexpected situations arise on the job site. Another key safety element is the overload protection system. These mechanisms kick in automatically when weights exceed safe limits, preventing damage to both equipment and personnel. According to recent reports from OSHA, companies that invest in proper safety gear see accident rates drop by around 40% over time. When workers handle heavy materials day after day, having reliable safety measures makes all the difference. Maintenance teams should check these systems regularly too. A good monthly inspection ensures everything works properly and stays compliant with current safety regulations across different manufacturing sectors.

Durable Braking and Anti-Drop Features

What makes European Type Hoists stand out is their robust braking system that keeps loads firmly in position, cutting down chances of unexpected drops. The anti-drop functions really matter when it comes to keeping workers safe around these machines, particularly where there's higher risk involved. Looking at insurance data shows that hoists equipped with better braking tech generally lead to fewer claims about equipment breakdowns, which speaks volumes about how dependable they actually are. Beyond just saving lives, these safety features stop costly damage to both machinery and whatever materials happen to be moving around. Maintenance folks should check those brakes and anti-drop components regularly to keep everything working properly. Taking this kind of hands-on approach maintains good safety practices and keeps operations running smoothly without interruptions.

4. Energy Efficiency and Long-Term Cost Savings

Reduced Power Consumption with Smart Motor Technology

The European style electric wire rope hoists come equipped with intelligent motor tech that manages power consumption while still delivering solid performance. Real world testing indicates that switching to these efficient models can slash electricity bills around 30 percent, which really adds up over time for factory operations. What makes them work so well is their ability to sense how heavy something is before lifting it, cutting down on wasted energy and actually making the motor last longer too. Many plant managers we've spoken to recommend going green with these systems when possible. They fit right into the broader movement toward saving energy worldwide, helping companies save money at the same time they reduce their environmental impact. For manufacturers looking to balance budgets with responsibility, this kind of upgrade makes good business sense.

Lower Maintenance Requirements for Budget Optimization

European type electric wire rope hoists generally need less maintenance work than older models, which saves companies money over time. When maintenance comes around less frequently, it cuts down on both labor expenses and equipment downtime, something that really matters when trying to keep production lines running smoothly. Looking at actual maintenance records shows these newer hoists tend to break down far less often than their predecessors did back in the day. For businesses thinking long term, getting these upgraded hoisting systems makes sense because they deliver steady performance while helping control operating budgets. Still worth remembering though, even with all these improvements, setting up a proper maintenance schedule remains important if companies want their hoists to last years instead of months and keep working efficiently throughout their service life.

To explore more about European Type Electric Wire Rope Hoists, click the following link: European Type Electric Wire Rope Hoist.

5. Technological Advancements and Remote Control Integration

Precision Control with Automated Systems

Automated systems have changed how we handle precision control in electric hoists, giving operators much better control over their loads. The increased accuracy means fewer mistakes happen on the job site, which cuts down on accidents that often come from human error. Manufacturing plants today really need this kind of precision because production demands are so high. Take automotive assembly lines for instance, where even small improvements in hoist operation can lead to big gains in productivity. Companies report workflow improvements of around 15-20% after switching to automated systems. As technology keeps improving, these controls get smarter too, adapting to different tasks across warehouses, construction sites, and industrial facilities where lifting operations vary widely from day to day.

Real-Time Monitoring via Smart Sensors

When smart sensors are built into European Type Electric Wire Rope Hoists, they allow for constant tracking of things like load weight, motor temperature, and cable tension during operation. This means operators get immediate alerts when something looks off, catching small problems before they turn into big headaches and saving money on repairs down the road. Factories that have adopted these sensor systems report around 30% fewer unexpected breakdowns compared to traditional setups, according to recent industry reports. The continuous stream of data from these hoists isn't just good for maintenance either it actually helps managers plan their workflow better, making sure cranes aren't sitting idle while other parts of the factory wait. Many manufacturers now run regular training sessions where workers learn how to read the sensor outputs properly, which not only boosts productivity but also creates safer working conditions as everyone becomes more aware of potential hazards in real time.

Wuhan Rayvanbo Import & Export Trade Co., Ltd stands out as a go-to source for European style electric wire rope hoists. Their products have built a reputation for lasting performance and getting the job done efficiently. What sets this company apart is how they work closely with clients to customize hoist solutions that actually fit real world industrial requirements. Many manufacturers struggle with standard equipment that doesn't quite match their unique workflows, but Rayvanbo takes the time to understand these challenges. By providing customized lifting solutions, they help factories and warehouses boost production rates while maintaining safe working conditions throughout their facilities.