Definiendo Grúa aérea y Grúas Móviles

Diseño Estructural de los Sistemas de Puente Grúa

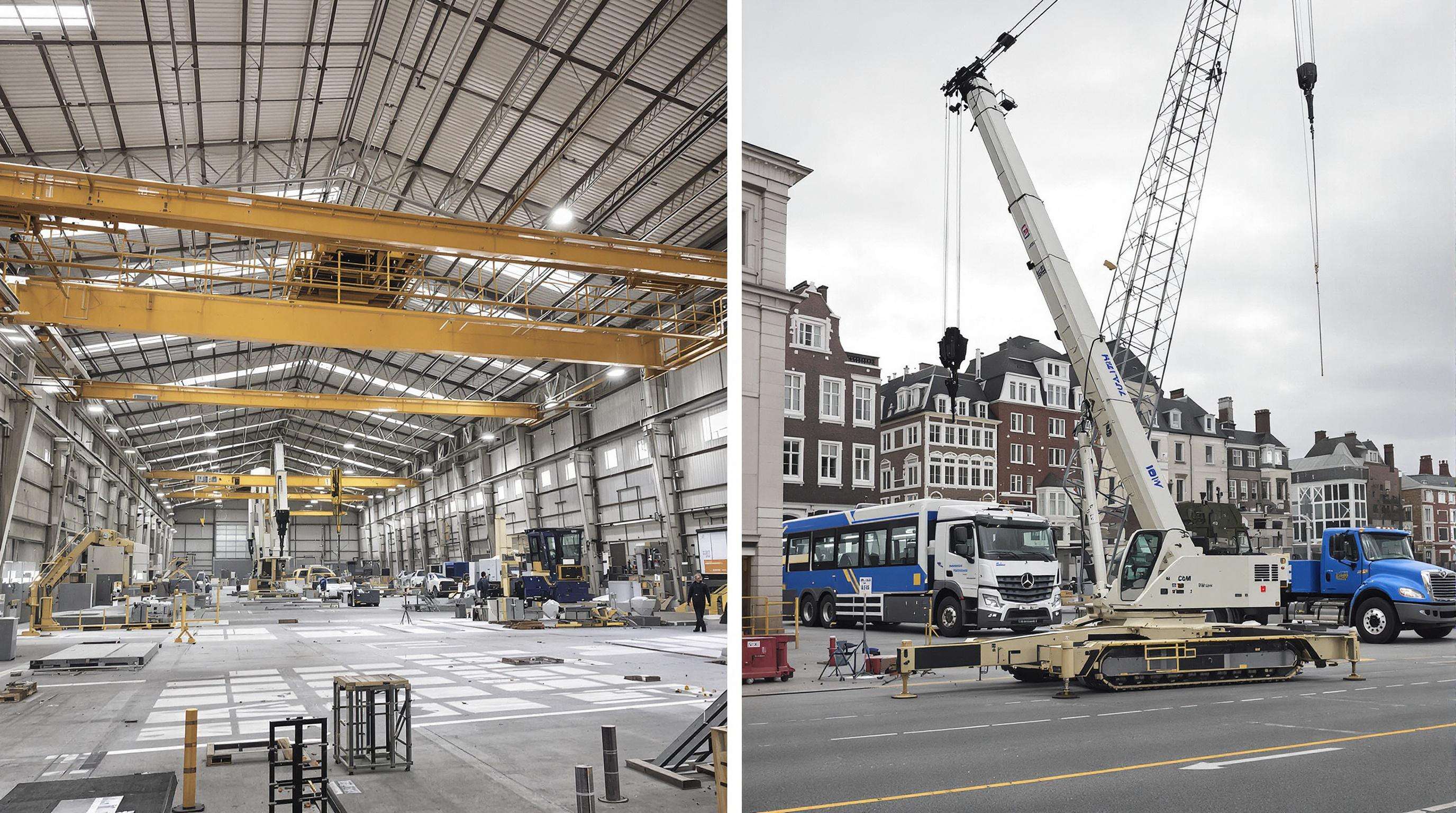

Las grúas puente funcionan sobre vigas carril que se instalan en las columnas del edificio o se fijan a las paredes, con un puente que se desplaza a lo largo del carril para mover el material de un extremo al otro. Utilizan polipastos eléctricos para un posicionamiento preciso de la carga, lo que las hace ideales para aplicaciones de producción que requieren múltiples puntos de elevación en un entorno controlado. Están construidas con acero soldado resistente para capacidades de hasta 500 toneladas (según la norma ASME B30), y nuestros carros estándar garantizan una mayor vida útil bajo cargas pesadas.

Configuraciones de grúas móviles y características de movilidad

Las grúas torre proporcionan elevación pesada en una ubicación fija; otras grúas utilizan capacidades de elevación y movimiento: equipos montados en camiones, sobre terrenos difíciles, orugas, y grúas telescópicas y articuladas sobre ruedas que son las más utilizadas. Se estabilizan mediante estabilizadores o contrapesos cuando no están estacionarias y pueden instalarse en varias ubicaciones en cuestión de horas. Los brazos telescópicos alcanzan hasta 60 metros para aplicaciones de gran altura, y la dirección en todas las ruedas permite maniobrar fácilmente en obras con espacio reducido. Sus sistemas hidráulicos están diseñados para un montaje y desmontaje rápidos, y algunos modelos tienen funcionalidad de "elevación y transporte" para levantar y mover cargas a distancias cortas sin necesidad de aparejos.

Aplicaciones industriales principales para cada tipo de grúa

Las grúas puente destacan en flujos de trabajo interiores de precisión:

- Producción : Transferencia de componentes en líneas de ensamblaje

- Almacenamiento : Apilamiento de inventario paletizado

- Metalurgia : Vertido de metal fundido en moldes

Las grúas móviles atienden proyectos exteriores dinámicos:

- Construcción : Colocación de vigas de acero en obras de rascacielos

- Infraestructuras : Instalación de componentes de puentes

- Energía : Instalación de turbinas eólicas en áreas remotas

Mientras que los sistemas puente optimizan el espacio en plantas con flujos de trabajo consistentes, las variantes móviles se adaptan a terrenos variables y cronogramas de proyectos.

Comparación de Capacidad de Elevación: Puentes Grúas vs Grúas Móviles

Manejo de Carga Máxima: Requisitos Industriales

Entre las grúas mencionadas, encontrará puentes grúas industriales capaces de manejar cargas pesadas y repetitivas de hasta 500 toneladas en acerías y líneas de producción automotriz, gracias a las vigas de carril estables y sistemas de doble gancho. Brazos telescópicos y contrapesos permiten a las grúas móviles levantar cargas especiales de hasta 1.200 toneladas para la instalación de turbinas eólicas o secciones de puentes. Sin embargo, los sistemas puente siguen siendo la opción principal para operaciones continuas con cargas pesadas, mientras que las unidades móviles para casos extremos de una sola elevación se utilizan predominantemente.

Precisión vs Flexibilidad en Elevación Pesada

Las grúas puente garantizan un posicionamiento milimétrico preciso con la ayuda de carros guiados por rieles, necesario para alinear con exactitud grandes carcasas de turbinas y accesorios sensibles para aeroespacial. Por su parte, las grúas móviles sacrifican una precisión exacta a cambio de la capacidad de adaptarse a los distintos terrenos de las obras, utilizando estabilizadores motorizados para ello. Esta variedad corresponde a un ~5% menos de repetibilidad posicional en comparación con los sistemas rígidos, por lo que los sistemas puente son más adecuados para flujos de línea de ensamblaje dominados por consideraciones de tiempo de ciclo.

Consideraciones sobre movilidad y acceso al sitio

Instalación fija vs Posicionamiento bajo demanda

Las grúas puente funcionan sobre un sistema de rieles a lo largo de la fábrica y son adecuadas para algunas de las aplicaciones más exigentes. Están instaladas permanentemente, pero pueden moverse con relativa facilidad. Por otro lado, las grúas móviles ofrecen una posición conveniente de uso en una variedad de terrenos, y el 83% de los gerentes de proyectos de construcción califican su maniobrabilidad alrededor de obstáculos como importante (Lifting Equipment Journal 2023).

Diferencias en el Tiempo de Configuración en Proyectos de Construcción

La instalación de grúas puente requiere de 2 a 3 semanas para el montaje de la vía y las integraciones eléctricas. Las unidades móviles se despliegan en menos de 4 horas, lo cual es fundamental en proyectos acelerados en los que el 68% de los retrasos provienen de cuellos de botella en la configuración del equipo. Sin embargo, las configuraciones móviles requieren esfuerzos diarios de reposicionamiento, mientras que los sistemas puente mantienen un estado listo para operar después de la instalación inicial.

Análisis de Costos: Economía Operativa Comparada

Instalación Inicial vs. Costos Recurrentes de Alquiler

Sistema de Grúa Puente - Costo Inicial Los sistemas de grúas puente son una gran inversión, con costos que oscilan entre $50,000 y $500,000 o más (fuente). En algunas instalaciones grandes, las grúas móviles funcionan bajo un sistema de alquiler con precios que van de $1,200 a $4,500 diarios, pero no generan costos permanentes de infraestructura. Sistemas Puente vs. Grúas Móviles: Lo anterior es un resumen de varios análisis de TCO (Costo Total de Propiedad), que indican que los sistemas puente son más rentables después de 3 a 5 años de uso frecuente, mientras que las grúas móviles son mejores para proyectos a corto plazo.

Requisitos de Mano de Obra por Tipo de Grúa

Las grúas puente reducen los costos laborales a largo plazo mediante operación semiautomatizada, generalmente requiriendo un solo operador certificado. El uso de grúas móviles requiere un equipo de 3 a 4 personas con un costo promedio por hora de mano de obra de $180 a $320. En cinco años, la mano de obra representa el 40% de los costos operativos de las grúas móviles versus el 15% en los sistemas puente.

Adaptabilidad Ambiental: Aplicaciones Interiores vs. Exteriores

Operaciones en Almacén vs Desafíos en Sitios de Construcción

Las grúas puente se destacan en almacenes con control climático donde la estabilidad de temperatura y operaciones limpias son prioritarias. Las grúas móviles dominan los sitios de construcción con una capacidad de escalada 37% mayor para manejarse en lodo, grava y variaciones de pendiente de hasta 15°.

Aprovechamiento del Espacio y Requisitos de Despeje

Las grúas puente optimizan el espacio vertical en instalaciones con alturas de techo de Ø24', operando en pasillos tan estrechos como 8'. Las unidades móviles requieren zonas de despeje de 360° con un promedio de 50' de diámetro para una articulación segura del brazo – un desafío en proyectos de modernización urbana donde OSHA exige una distancia mínima de 30' de proximidad a líneas eléctricas.

Marco de Decisión para la Selección de Grúas

6 Factores Críticos en la Especificación del Equipo

La selección de grúas industriales requiere equilibrar la capacidad de carga, las limitaciones espaciales, la frecuencia de elevación, los requisitos de movilidad, las condiciones ambientales y el presupuesto. Los sistemas elevadores son excelentes para elevaciones repetitivas en interiores con tolerancias estrictas de peso, mientras que las unidades móviles son ideales para proyectos exteriores que requieren reubicaciones frecuentes.

Matriz de Casos de Uso: Fabricación vs Construcción

| Requisito | Prioridad en Fabricación | Prioridad en Construcción |

|---|---|---|

| Precisión de posicionamiento | ±1 cm | ±15 cm |

| Ciclos Diarios de Movimiento | 150+ | 15—20 |

| Tolerancia al Tiempo de Configuración | 1—2 horas | Implementación Inmediata |

Futurizar su Estrategia de Manipulación de Materiales

Las operaciones modernas cada vez más favorecen sistemas de grúas adaptativos con capacidades de carga modulares para acomodar reconfiguraciones en las líneas de producción. Las interfaces de carros/polipastos de doble propósito reducen los costos de modernización en un 40%. Los operadores líderes ahora exigen monitoreo de carga habilitado para IoT, con un 62% de las instalaciones encuestadas planeando flujos de trabajo de inspección asistidos por drones para 2025.

Preguntas frecuentes

¿Cuál es la principal diferencia entre grúas puente y grúas móviles?

Las grúas puente generalmente se usan para aplicaciones interiores con posicionamiento preciso de cargas, mientras que las grúas móviles se emplean en entornos exteriores donde se requiere flexibilidad y maniobrabilidad.

¿Cuánto tiempo toma instalar grúas puente comparado con grúas móviles?

La instalación de grúas puente normalmente toma de 2 a 3 semanas, mientras que las grúas móviles pueden desplegarse en menos de 4 horas.

¿Qué tipo de grúa es más rentable para uso prolongado?

Las grúas puente suelen ser más rentables tras un uso frecuente durante 3 a 5 años. Las grúas móviles son más adecuadas para proyectos a corto plazo.

¿Cuáles son los requisitos de mano de obra para operar estas grúas?

Las grúas puente generalmente requieren un operador certificado, mientras que las grúas móviles exigen un equipo de 3 a 4 personas.

¿En qué destacan las grúas puente en comparación con las grúas móviles?

Las grúas puente destacan en entornos interiores que requieren operaciones precisas, mientras que las grúas móviles ofrecen versatilidad en sitios exteriores con terrenos variables.

Tabla de Contenido

- Definiendo Grúa aérea y Grúas Móviles

- Comparación de Capacidad de Elevación: Puentes Grúas vs Grúas Móviles

- Consideraciones sobre movilidad y acceso al sitio

- Análisis de Costos: Economía Operativa Comparada

- Adaptabilidad Ambiental: Aplicaciones Interiores vs. Exteriores

- Marco de Decisión para la Selección de Grúas