Chain Hoist: Lifting Performance and Duty Cycle for 2-Ton Loads

Rated Capacity vs. Real-World Safe Working Load Under Continuous Use

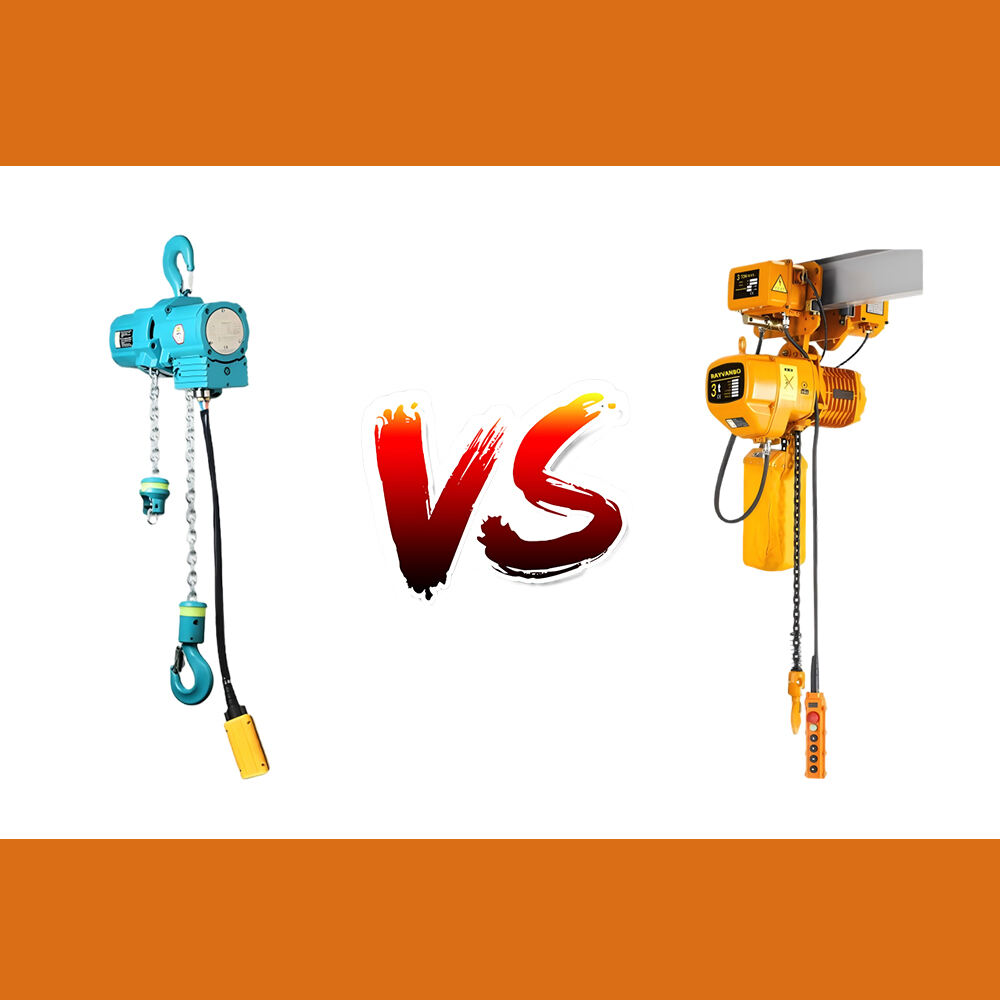

Electric chain hoists and wire rope hoists both come with a stated 2-ton capacity, though what they can actually handle safely differs when used continuously. The alloy steel chains found in electric models tend to hold up better against bending or warping, so they maintain most of their rated strength in practice. Wire rope systems tell a different story though. Their capacity tends to drop slightly over time because the ropes naturally stretch and the drums wear down from repeated use. These small losses build up with every lift cycle. That's why many experienced engineers recommend adding around 10 to 15 percent extra capacity beyond the listed rating for any job requiring constant 2-ton lifting. This gives some breathing room for the motor, gears, and bearings which take tiny hits each time something gets lifted, even if it seems fine at first glance.

Duty Rating Comparison: How Intermittent vs. Frequent 2-Ton Lifting Impacts Hoist Longevity

The duty rating system, which includes categories like H3 for moderate workloads and H4 for heavy lifting, basically tells us how fast these 2 ton lifts should run without breaking down. Electric chain hoists really shine when things get busy on the shop floor, say around 30 lifts per hour or more. They handle heat better because of their smaller size and can start and stop quickly, which makes them great for those assembly line operations where downtime costs money. Wire rope hoists work fine for medium paced jobs, about 10 to 20 lifts each hour, but they need breaks between runs to keep motors from getting too hot if used all day long. Tests have shown that pushing equipment beyond what's listed on the spec sheet can shorten lifespan anywhere from 40% to 60%. That's why sticking to the manufacturer's recommended duty classification matters so much for keeping machines running reliably over time instead of constantly replacing parts.

Physical Fit and Installation Requirements in 2-Ton Environments

Headroom, Lift Height, and Spatial Constraints Across Workshops, Docks, and Maintenance Bays

Getting enough headroom matters a lot when setting up those 2-ton hoists. Electric chain hoists take up about 30 to 40 percent less vertical space compared to their wire rope counterparts. That makes all the difference in maintenance areas with low ceilings where available headroom might be 12 feet or less. The chains on these electric models stay contained within the unit itself, so there's no need for extra drum stacking or complicated reeving arrangements. Wire rope hoists need more room because they have drums that spin around and layers of rope that build up over time. These are generally better fits for taller spaces like warehouse bays with at least 20 feet of clearance between floor and ceiling. Before installation, it pays to check exactly how much lifting height is needed versus what's actually available. Look out for things like overhead beams, ventilation ducts, or even lighting fixtures that might get in the way. For shops where every inch counts, going with electric chain hoists gives maximum vertical movement without sacrificing anything else.

Compactness of Electric Chain Hoists vs. Wire Rope Hoist Drum Assembly and Reeving Footprint

Electric chain hoists take up far less room for 2 ton jobs compared to traditional wire rope models, sometimes cutting down on space requirements by about half. The compact design of these hoists means they don't need those big drums or complicated reeving systems anymore, which makes them perfect for tight spots like narrow assembly lines or crowded maintenance zones. Wire rope hoists tell another story though. They actually need extra horizontal room just for the drum to spin plus all those guide sheaves around it. This adds between 25% to 35% more space needed overall. So while these older style hoists won't work well in cramped quarters, they still have their place in larger factories where there's plenty of floor area available without worrying about every square inch.

Application-Specific Strengths: When to Choose Electric Chain Hoist vs. Wire Rope Hoist for 2-Ton Tasks

When choosing between electric chain and wire rope hoists for handling 2-ton loads, it's really about what works best for the job at hand rather than just looking at weight specs. Electric chain hoists tend to be the better bet when there's not much space overhead, like in maintenance areas or older workshop setups that need upgrading. They also work well for jobs where lifting happens now and then instead of constantly, such as fixing machinery or running production batches. The money saved upfront matters too. These hoists don't cost as much initially, require less upkeep overall, and generally install quicker than their wire rope counterparts, making them a smart investment for many industrial settings.

Wire rope hoists really excel in places where things need to work reliably day after day, like busy loading docks, factory assembly lines running nonstop, or when moving materials outside all year round. These systems handle those tough 2 ton loads every single day without breaking down. The multi strand steel cables just last longer under constant stress compared to regular chains, which means less time spent fixing worn out parts. When conditions get rough with lots of dust floating around, humidity making everything damp, or temps pushing past 100 degrees Fahrenheit, the special corrosion resistant wire ropes still hold up better than normal chain materials would. For jobs that require pinpoint accuracy, the low stretch nature of wire rope makes all the difference. The smoother operation allows positioning within half an inch either way, something that matters a lot when aligning big machines or placing delicate components correctly. Outdoors especially, galvanized or stainless steel wire ropes stand up to sunlight and extreme cold much better than unprotected chains that tend to seize up when it gets below freezing point.

Operational Factors: Control, Speed, Precision, and Environmental Suitability

Lifting Speed, Positioning Accuracy, and Control Responsiveness at 2-Ton Capacity

Electric chain hoists generally have faster lifting speeds around 24 feet per minute when handling two ton loads which makes them great for moving materials quickly through production areas or staging spots. Wire rope models focus more on getting things just right than going fast. The ropes don't stretch much so they stay within about half a percent accuracy when positioning heavy stuff, something really important during detailed assembly work or setup processes. When it comes to how responsive these hoists are, there's a difference based on what kind we're talking about. Chain versions accelerate pretty quickly making them good for all those repeated lifting tasks day after day. Meanwhile, wire rope systems handle speed changes more smoothly, allowing operators to slow down carefully and place loads exactly where needed without causing damage.

Indoor/Outdoor Use, Dust, Moisture, and Temperature Resilience for 2-Ton Industrial Settings

Wire rope hoists tend to hold up much better in tough environments compared to other options. Take models with IP55 ratings for instance these can handle pretty extreme temperatures ranging from minus 40 degrees Celsius all the way up to 60 degrees Celsius without breaking down. They also keep out dust and water jets which matters a lot in places like food processing areas foundries or those big marine terminals where conditions get rough. Chain hoists are another story altogether. These need constant greasing when exposed to dirt or moisture leading to maintenance expenses that jump around 15 to 20 percent higher in those harsh settings. For outdoor setups galvanized or stainless steel wire ropes work wonders against corrosion problems that would weaken regular carbon steel chains over time. And let's not forget about facilities that undergo frequent washdowns such as pharmaceutical manufacturing sites or dairy processing plants. Stainless steel wire rope assemblies completely remove the risk of contamination from flakes or rust spots making them essential for operations that must comply with strict regulations while keeping things running smoothly day after day.

FAQ

1. What is the duty rating system for hoists?

The duty rating system includes categories such as H3 for moderate workloads and H4 for heavy lifting. It helps determine how fast the 2-ton lifts should operate without breaking down.

2. Why do electric chain hoists require less vertical space?

Electric chain hoists occupy less vertical space because their chains are contained within the unit itself, eliminating the need for additional drum stacking or reeving.

3. How do wire rope hoists handle tough environmental conditions?

Wire rope hoists, especially those with corrosion-resistant material, excel in harsh environments like dust, moisture, and extreme temperatures. Their IP55 rating ensures resilience against such conditions.

4. What factors are important when choosing between electric chain and wire rope hoists?

Key factors include physical space constraints, load frequency, environmental conditions, and the job requirements such as precision or lifting speed.

Table of Contents

- Chain Hoist: Lifting Performance and Duty Cycle for 2-Ton Loads

- Physical Fit and Installation Requirements in 2-Ton Environments

- Application-Specific Strengths: When to Choose Electric Chain Hoist vs. Wire Rope Hoist for 2-Ton Tasks

- Operational Factors: Control, Speed, Precision, and Environmental Suitability