Kiçik İş Stansiyaları üçün Kompakt Dizayn və Yer Effektivliyi

Ən Az Yer Ilə İş Mekanını Maksimum Şəkildə İstifadə Edin

Bu günklər sənaye dünyası sürətlə hərəkət edir və kompakt dizaynlar heç olmasa əvvəl olduğu qədər vacibdir. Sıx yerlərdə qalmış şirkətlər işlərini hamı üçün təhlükəsiz və səliqəli şəkildə yerinə yetirmək üçün hər bir düym yerinə yaradıcı həllər tapmalıdırlar. Sənaye göstəriciləri son zamanlarda müxtəlif sahələrdə, xüsusilə də kiçik istehsalat müəssisələrində və tektoloji sahədə fəaliyyət göstərən startap firmalarda daha kompakt iş stansiyalarının artıq qurulduğunu göstərir. Yer məhdud olduqda, şirkətlər düzgün işləyən konfiqurasiyadan və ya işçilərin təhlükəsizliyindən imtina etmədən yaradıcı həllərə getməlidirlər. Əslində heç kəs tavanı qənaət etmək üçün sıx şərait yaratmaq istəmir.

Kranların kompakt dizaynı onları şaquli sahədən yaxşı istifadə etməyə uyğun edir. Döşəmə sahəsi məhdud olan mağazalar və ya anbarlar üçün bu, şirkətlərin iş sahəsini dağınıq bir halə salmadan zəruri avadanlıqları quraşdırmaq üçün vacibdir. Daha çox açıq döşəmə sahəsi mövcud olduqda istehsalçılar əməkdaşlarının yanında əlavə maşınlara yer sığdırabildiyini görür və bu ümumiyyətlə əksər əməliyyatlarda daha yaxşı iş axını və daha sürətli istehsal vaxtlarına səbəb olur.

Çoxsağlam örtü və 360-dərəcə li esneklik

Dövran diapazonu ilə materialların hərəkətini optimallaşdırmaq

JIB qollarının bir çox iş yerində bu qədər qiymətli olmasının səbəbi onların 360 dərəcə ətrafında fırlana bilmə qabiliyyətidir. Bu xüsusiyyət işçilərə bütün iş sahəsində çox daha yaxşı nəzarət imkanı verir. Qolun mərkəzi dirəyi ətrafında azadca fırlanmasına icazə verilir, bu da ağır əşyaları yerləşdirərkən bütün maşının daim hərəkət etdirilməsinə ehtiyac yaratmır. Avto təmiri mağazaları və zavodlar xüsusilə bu dönmə qabiliyyətinə malik modelləri quraşdırdıqdan sonra işlərin daha sürətli həyata keçirildiyini müşahidə edirlər. Bəzi şirkətlər isə tam dönməli JIB qollarına keçiddən sonra hər gün iş həcminin təxminən 20% artıdığını bildirirlər, çünki materiallar mağaza zərində daha tez və dəqiq hərəkət edir. Kiçik iş sahələri düzgün qol fırlanma variantlarından xüsusilə faydalanır, çünki orada hər düym belə əhəmiyyətlidir. Texnologiya startapları avadanlığı dar küncə yerləşdirməyə çalışarkən və ya kiçik istehsalat müəssisələri gündəlik istehsalatın artırılması üçün mübarizə apararkən tam dövrəli dönmə imkanına malik JIB qolunun olması əməliyyatlarda fərqi yaradan amil olduğunu müşahidə edirlər.

Əyləm uzunluğlarının hədəflənmiş iş stansiyası ehtiyacına uyğun tənzimlənməsi

Dəyişən qol uzunluqları bu qaldırıcıların müxtəlif çəkilər və hündürlüklərlə məşğul olarkən qiymətli yer səthini itirmədən inanılmaz dərəcədə çeviklik göstərməsinə imkan verir. Dəyişiklik etmək bacarığı JIB qaldırıcılarının iş yerlərində, anbarlarda və ya tikinti sahələrində də müxtəlif yerlərdə yaxşı işləməsinə kömək edir. Məsələn, istehsalat sahələrini götürək, burada işçilər gün boyu müxtəlif formalar və ölçülərdə materiallarla işləyirlər. Dəyişən qollarla operatorlar növbəti qaldırılacaq materiala uyğun olaraq qaldırıcı parametrlərini dərhal yerində tənzimləyə bilərlər. Əksər insanlar bilirlər ki, dəyişən uzunluqların olması materialların hərəkət zamanı daha yaxşı nəzarət altında saxlanması ilə təsadüflərin azalmasına kömək edir. Bundan əlavə, əməliyyatlar daha hamar gedir, çünki geri qayıtmalar və mövqeləndirmələr azalır. Sənaye statistikası da bunu təsdiqləyir və JIB qaldırıcılarında dəyişən qol xüsusiyyətləri olan iş yerlərində təsadüflərin təqribən 15% azalmasına səbəb olur.

Kiçik Ölçülü Endustriyal Sənədlər üçün Personallaşdırma

Həcmi Personallaşdırma: Hədəfləndirici Dəstədən 5 Tonlu JIB Kranlara Qədər

Kiçik ölçülü sənaye qaldırma ehtiyacları üçün düzgün ölçünü seçmək çox vacibdir. JIB kranları ən müxtəlif ölçülərdə olur. Kiçik əşyaların hərəkət etdirilməsi üçün yararlı yüngül modellərdən tutmuş, 5 ton həcmində ağır işlər üçün modellərə qədər hər şey mövcuddur. İş yerinin ölçüsündən və dəyişən yüklərdən asılı olaraq ən uyğun modeli seçmək iş prosesini xeyli yaxşılaşdırır. Ancaq səhv ölçülü model seçmək yalnız iş səmərəliliyini azaltmır. Təhlükəsizlik də burada əsas məsələlərdən birinə çevrilir, xüsusilə ki, kiçik müəssisələrin əksəriyyəti belə təhlükəsizlik qaydalarına ciddi şəkildə riayət etməlidir. Bu kranlardan gündəlik istifadə edən insanlar tez-tez düzgün modeli seçməyin iş prosesini necə dəyişdiyini danışırlar. Məhsuldarlıq artır, maşınların sıradan çıxma ehtimalı isə azalır ki, bu da həftənin sonunda hər kəsi sevindirir.

Qaldırma qabiliyyətinin nə qədər olduğu barədə dəqiq məlumat sahibliyi qurğuş qurğuşların təhlükəsizliyi ilə bağlı qaydalara riayət etməkdə çox əhəmiyyətlidir. Şirkətlər bu təlimatlara əməl etdikdə, onlar işçilərin təhlükəsizliyini təmin edərkən eyni zamanda işləri daha səliqəli şəkildə həyata keçirə bilirlər. İşə uyğun qurğunun seçilməsi gündəlik rejimdə iş sahəsində baş verən proseslərə tam uyğun gələn daha yaxşı iş axını yaradır. Heç kəs qurğuşların yükünə qurğuş qurğuş görmək istəməz, çünki belə hallar qəzalara səbəb olur. Bütün bunların düzgün edilməsi işçilərin avadanlıqların işdən çıxması və ya təhlükəli vəziyyətlərin qəflətən yaranması ilə bağlı heç bir narahatlıq yaşamadan işləmələrinə imkan verir.

Unikal dizaynlar üçün spesial montaj seçimləri

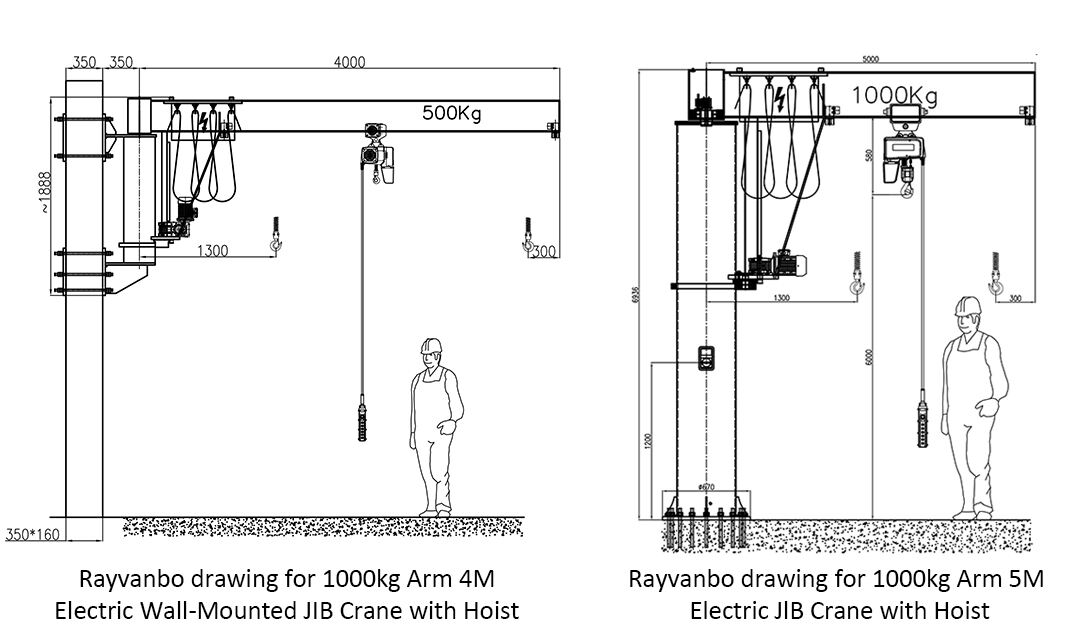

Qeyri-adi zavod sahələri ilə məşğul olarkən JIB kranları müxtəlif quraşdırma seçimləri ilə seçilir. Bəzi mağazalar dələlər üzərində quraşdırmaqla qiymətli yerlərdən qənaət edir, digərləri isə ağır qaldırma işləri zamanı daha möhkəm hiss edən yer üzərində quraşdırılmış versiyaları üstün tutur. Bu müxtəlif konfiqurasiyalar faktiki olaraq iş yerində yaranan müəyyən çətinliklərlə mübarizə aparmaqda, işləri yavaşlatmadan və məhsuldarlığı azaltmadan həll edir. Alətlərin və hissələrin hər tərəfə yayıldığı möhtəşəm maşın zavodunu götürün – divarda quraşdırılmış JIB kranını doğru yerdə qoymaq materialların təhlükəsiz şəkildə daşınmasında böyük fərq yaradır, bu da bizim real istehsalat mühitlərində çox vaxt şahid olduqlarımızdır.

Quraşdırmanı düzgün etmək, qurğunun gündəlik işləmə keyfiyyətinə və problemlər olmadan işləmə müddətinə təsir göstərir. Əgər JIB qaldırıcısı əvvəldən düzgün quraşdırılıbsa, daha yaxşı işləyir və gələcəkdə təmir tələb etmir, bu da uzun müddətdə xərclərin qənaət edilməsinə kömək edir. Şirkətlər hansı quraşdırma həllinin onların vəziyyətinə daha uyğun olduğunu müəyyən etməyə vaxt ayırıblar və bu qaldırıcılar üzrə investisiyalarından real dəyər əldə edirlər. Qurğular uzun müddət etibarlı qalır, səmərəli işləməyə davam edir və ümumi istehsalatın məhsuldarlığının artırılmasına kömək edir. Seçimləri araşdıranlar üçün Wuhan Rayvanbo tərəfindən təklif olunan bir neçə növ JIB qaldırıcısı mövcuddur. Onların məhsulları möhkəm konstruksiyası və sıx yerlərdə və ya xüsusi tələblər olan hallarda işləyən istehsalçılar tərəfindən üzləşilən real problemləri həll edən kifayət qədər ağıllı dizayn xüsusiyyətləri ilə seçilir.